Common Issues

WITH LOW QUALITY WALL AND ROOF PANELSLeakage from Poor Jointing

Substandard jointing systems and unskilled installations often lead to leaks and long-term structural damage.

Paint Peel-Off

Inadequate primer and paint thickness cause early deterioration and poor surface aesthetics.

Rusting Over Time

Lower galvanization and coating specs often result in panel corrosion within weeks or months.

EPACK Sandwich Panels

HOW THEY SOLVE THESE PROBLEMSSeamless Jointing System

Our specially designed jointing system is air-tight and prevents leakage even after several years of usage.

Superior Paint Finish

We use top-grade primer and high-thickness paint coatings for long-lasting aesthetics and protection.

Rust-Resistant Panels

Built with pre-painted galvanized steel and undergoing 47+ quality checks, our panels resist rust even in the most demanding conditions.

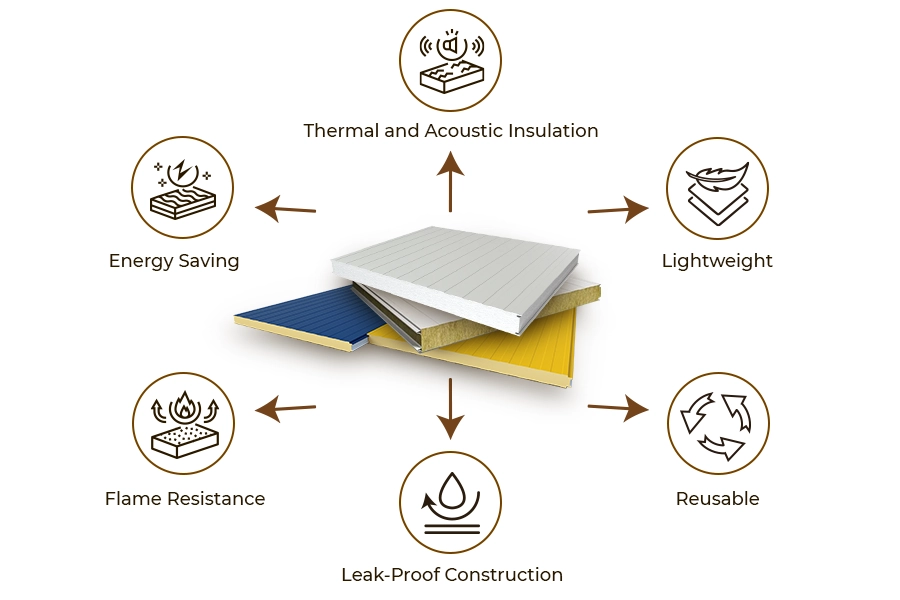

PUR, PIR, EPS, Rockwool & Glasswool Sandwich Panels – Properties & Benefits

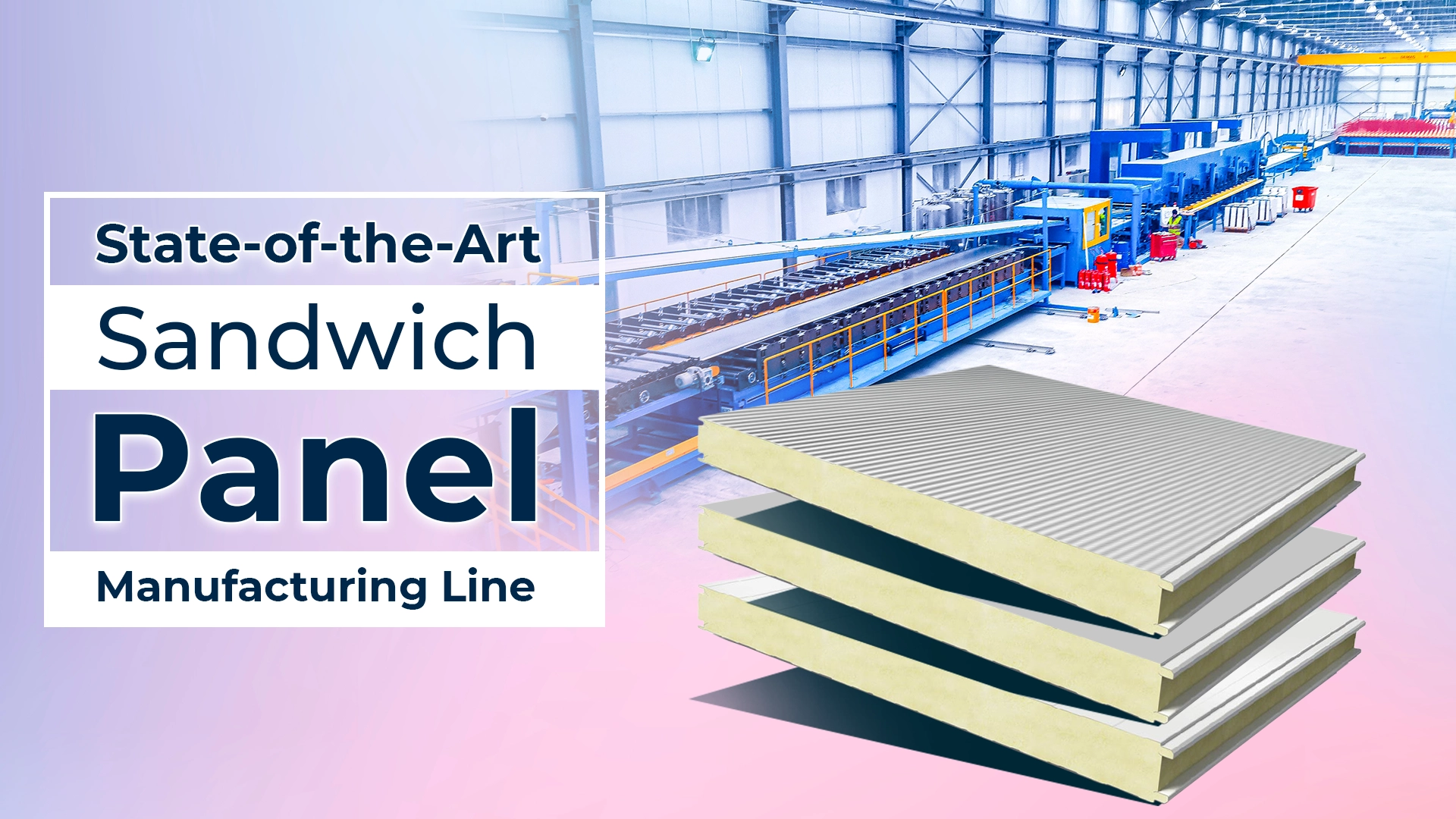

At EPACK Prefab, we manufacture a wide range of insulated sandwich panels including PUF, PIR, EPS, Rockwool, and Glasswool – all designed to meet diverse project requirements across industrial, commercial, and residential sectors. These high-performance panels offer excellent thermal insulation, structural strength, and long-lasting durability. Whether you require panels from a continuous or discontinuous line, we deliver solutions tailored to your application.

Introducing Our Complete Range of Sandwich Panels

At EPACK Prefab, we offer advanced sandwich panels manufactured via both Continuous and Discontinuous Production Lines to ensure consistent quality and rapid delivery across India.

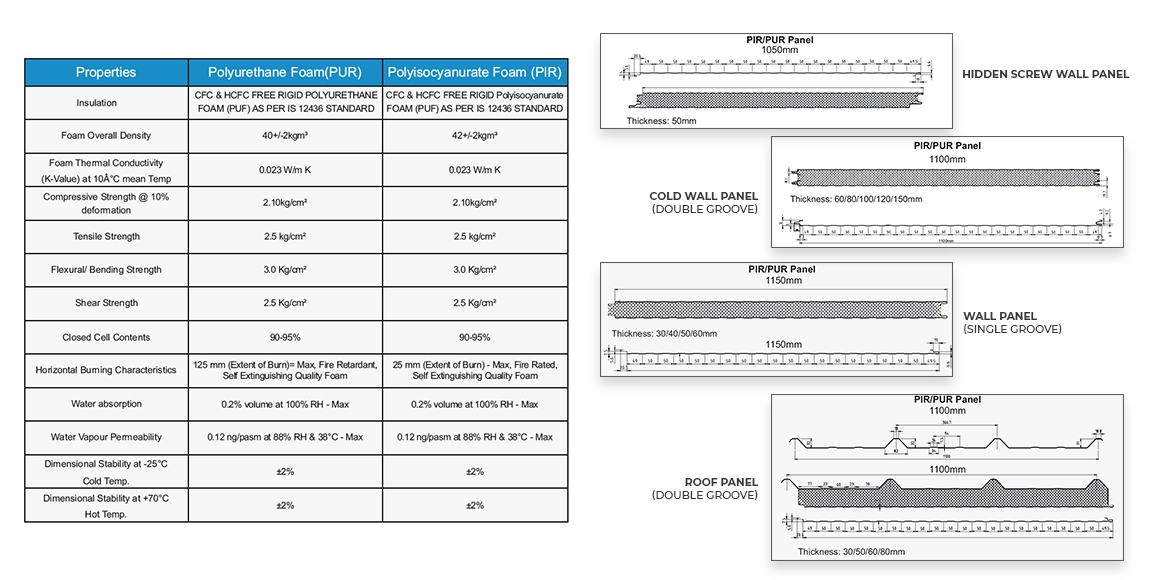

PUF/PIR Panels

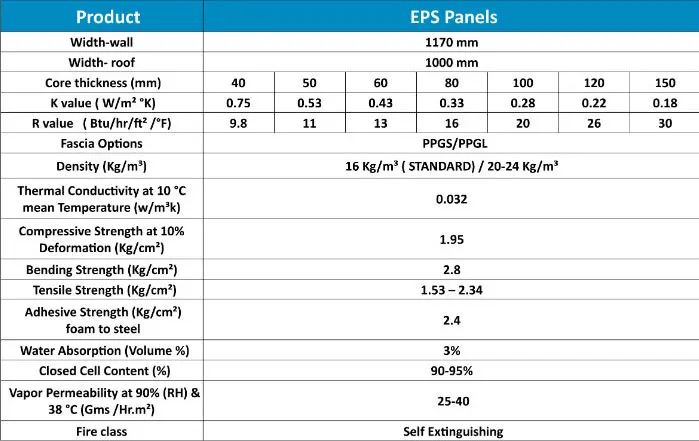

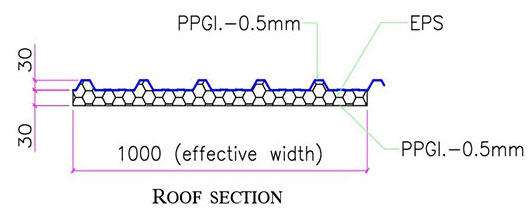

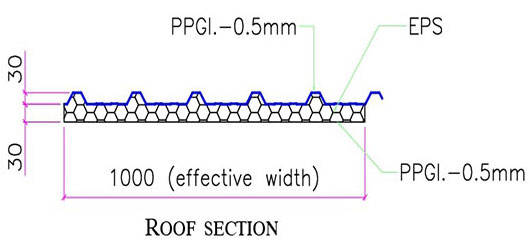

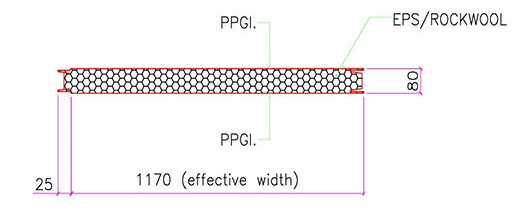

EPS PANELS

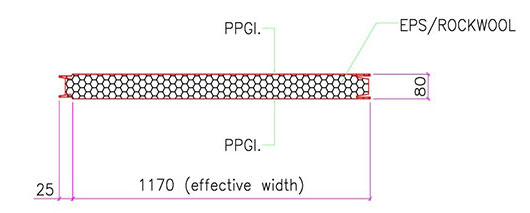

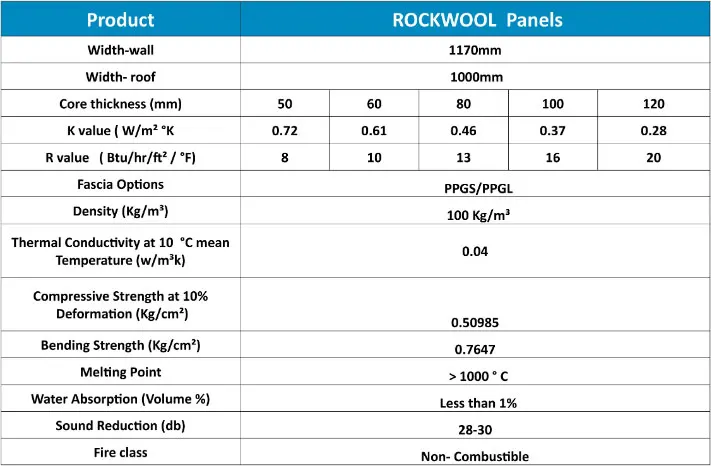

ROCKWOOL PANELS

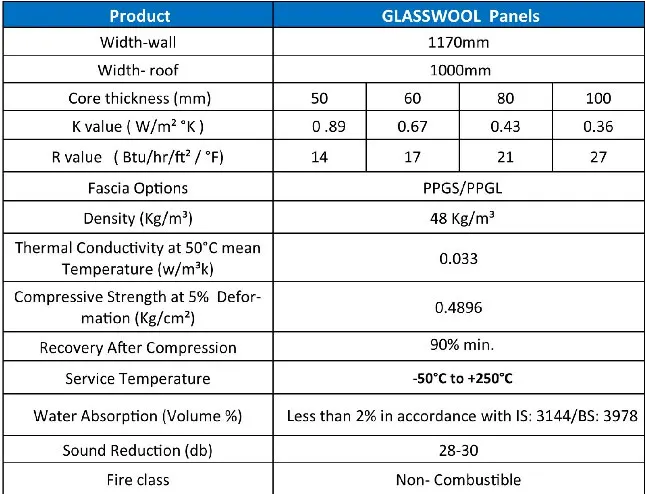

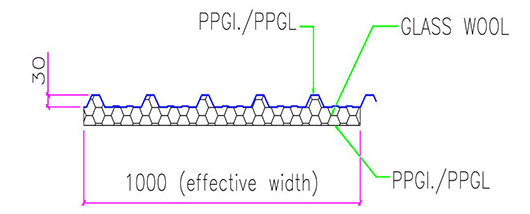

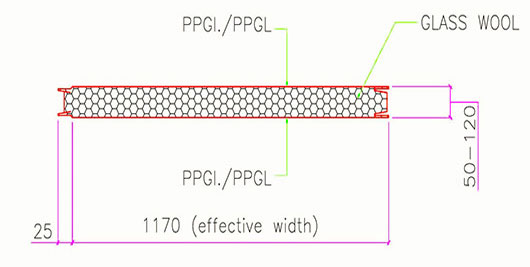

GLASSWOOL PANELS

Technical Details

EPACK Sandwich Panels Applications

EPACK Sandwich PanelsWe, at EPACK Prefab, are one of the largest Sandwich Panel Manufacturers in India and offer a wide range of insulating panels that are compact and suitable for a wide variety of applications such as agriculture, commercial buildings, healthcare facilities, cold storage units, warehouses, and many others.

For Further Inquiries Call

(+91) 959 948 5789If you have a query, please feel free to call us. Our team will assist you.

Superior Sandwich Panel Solutions – Right Where You Need Them

Tell us your requirements — we will execute them to perfection!

Benefits from EPACK Prefab

✅ Leak-Proof Roof and Wall Panel Systems

Designed for all-weather protection and lasting durability

🏭 Strict In-House Quality Checks

Ensuring consistent performance and product excellence

📏 6876 SQM Production Capacity Per Day

Capable of handling bulk and time-sensitive orders with ease

🛠️ 25+ Years of Manufacturing Excellence

Proven industry leader in prefab and insulation technologies

💡 Superior Thermal Performance

Save on energy costs with low thermal conductivity panels

Why Choose EPACK PREFAB?

India’s Trusted Sandwich Panel Manufacturer

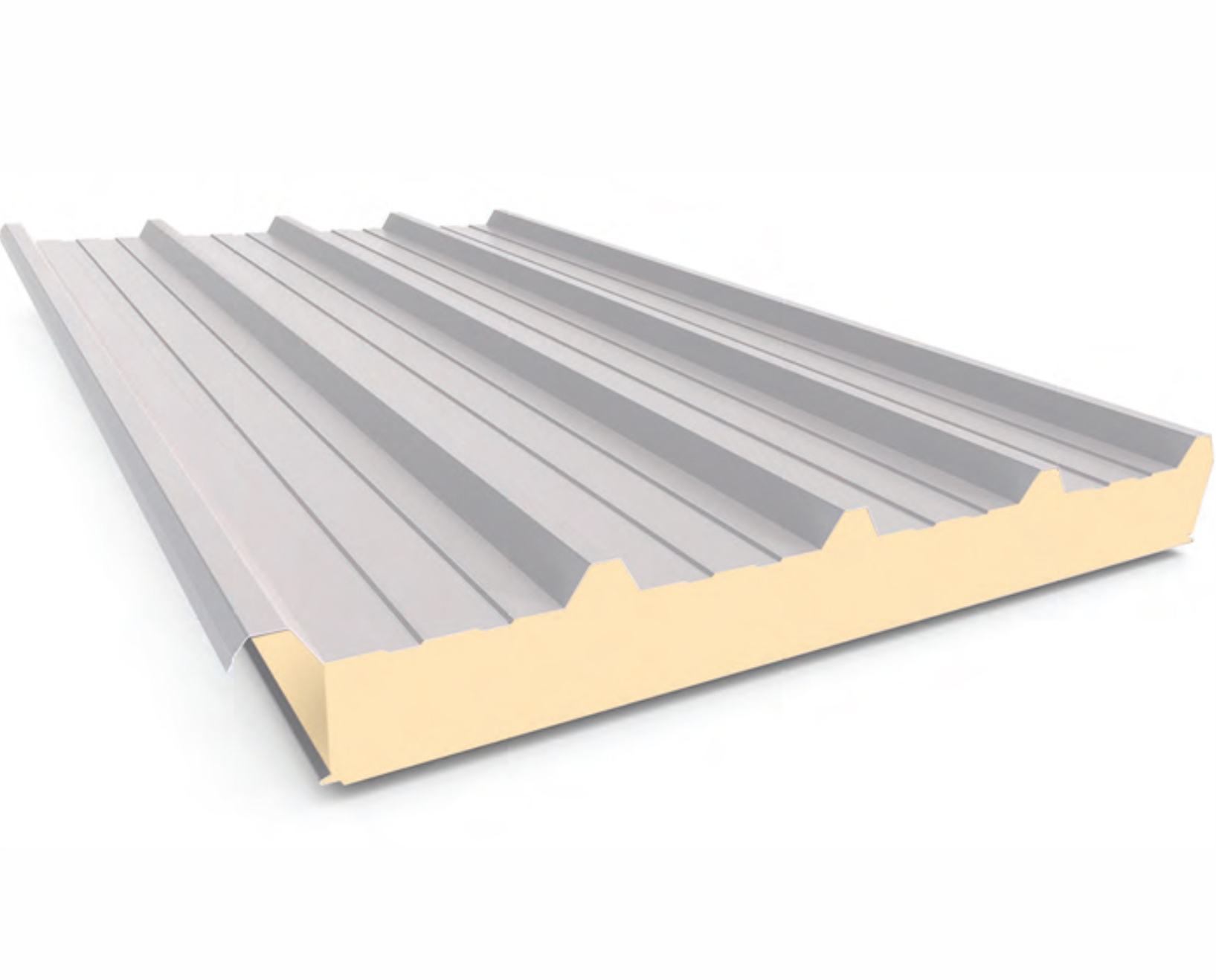

EPACK’s insulated sandwich panels are engineered for strength, efficiency, and versatility. Crafted from dual metal sheets with a high-performance insulating core, they provide an ideal cladding solution for both roofing and walling applications.

🏗️ Over 25 Years of Prefab Industry Expertise

A legacy of delivering innovative construction solutions

🧪 Thorough Quality Testing

Each panel goes through multi-stage QC before dispatch

🔧 End-to-End Execution Capability

From design to on-site installation by our in-house teams

🚛 PAN India Delivery Network

Efficient logistics to deliver anywhere across the country

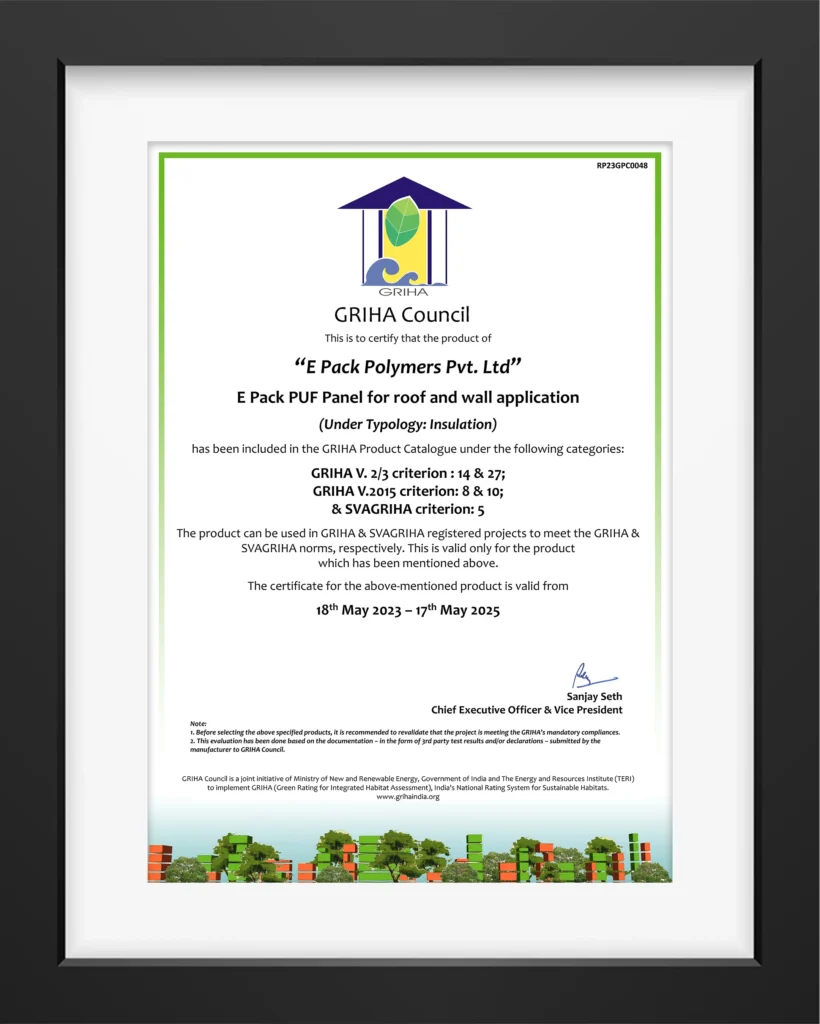

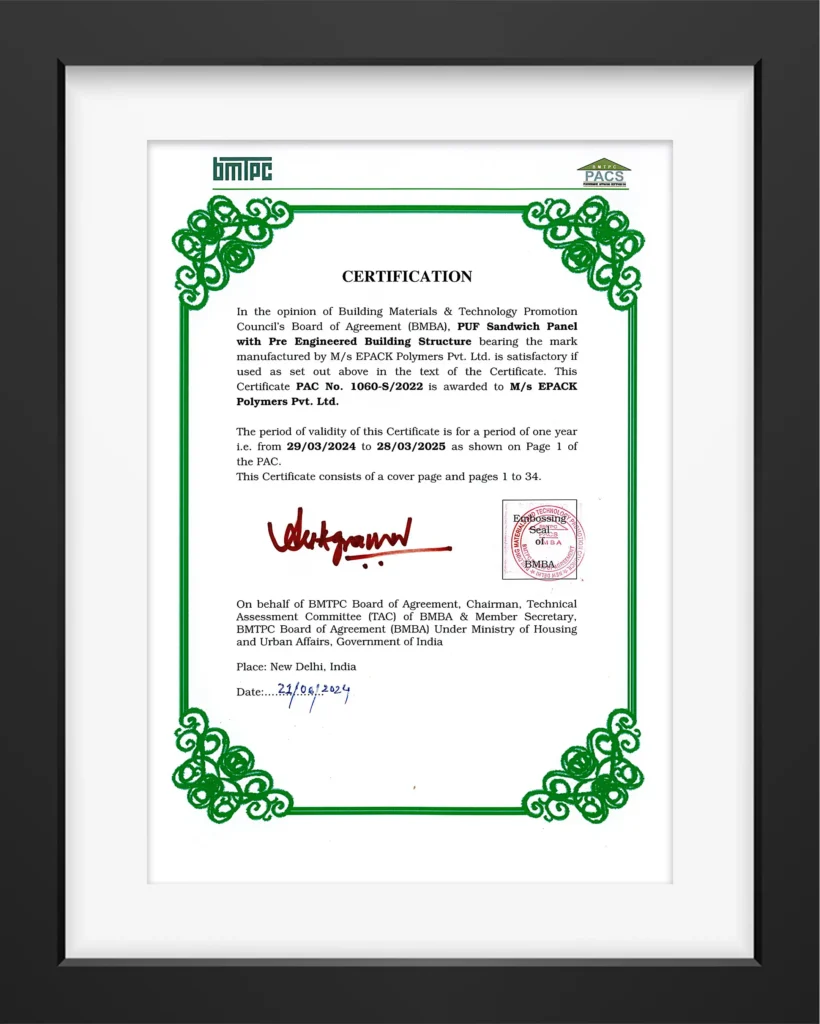

Certified by Leading Institutions – GRIHA & BMTPC

What Clients Says?

Our Quality Certification

Delivered Projects

EPACK Prefab’s insulated sandwich panels are ideal for a wide range of applications. Manufactured through our latest state-of-the-art continuous production line, these panels ensure superior consistency, thermal performance, and structural strength.

Our flagship PUF Panels are composed of a high-density rigid core, sandwiched between durable metal sheets. Alongside PUF, we also produce EPS, Rockwool, and Glasswool Panels—all manufactured in-house at our advanced facility.

Known for their quick installation, cost-effectiveness, and excellent insulation, our sandwich panels are widely used in industrial and commercial buildings, including roofs, exterior walls, cold storage units, warehouses, and prefabricated structures.

Common Questions

-

01 What are sandwich panels used for?

Sandwich panels are widely used in industrial buildings, cold storages, clean rooms, prefab structures, and commercial enclosures due to their superior insulation and quick installation properties.

-

02 What are the different types of sandwich panels you offer?

At EPACK Prefab, we manufacture four types of sandwich panels – PUF/PIR (Polyurethane Foam), EPS (Expanded Polystyrene), Rockwool, and Glasswool panels – to suit varied thermal, acoustic, and fire-resistance requirements.

-

03 What are the advantages of using sandwich panels in construction?

Sandwich panels are lightweight, thermally insulated, easy to install, cost-effective, and durable, making them ideal for fast-track and energy-efficient building projects.

-

04 Are sandwich panels water and weather resistant?

Yes, all our panels offer excellent weather protection. Especially PUF and EPS panels have low water absorption, while Rockwool and Glasswool panels add superior fire and acoustic insulation.

-

05 What is the life expectancy of sandwich panels?

With proper installation and maintenance, our sandwich panels typically last 20–25 years, making them a long-term and reliable solution.

-

06 What thickness options are available in your sandwich panels?

Our panel thickness options range from 30mm to 150mm, depending on the application. Common choices include 50mm, 75mm, and 100mm, with custom sizing available on request.

-

07 What is the typical density of these panels?

-

PUF Panels: 40 ± 2 kg/m³

-

EPS Panels: 16–20 kg/m³

-

Rockwool & Glasswool Panels: 48–96 kg/m³, based on application

-

-

08 Are your panels certified?

Yes, EPACK Prefab panels are BMTPC and GRIHA certified, ensuring compliance with industry standards for performance, sustainability, and safety.