Get Higher Insulation & Durability With Our Rockwool Panels

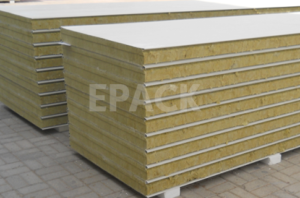

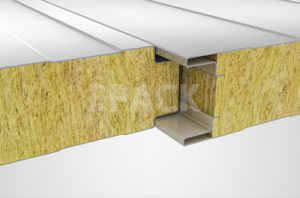

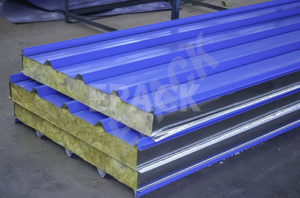

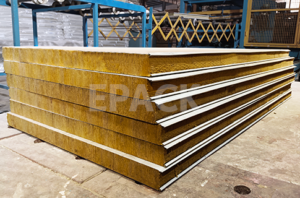

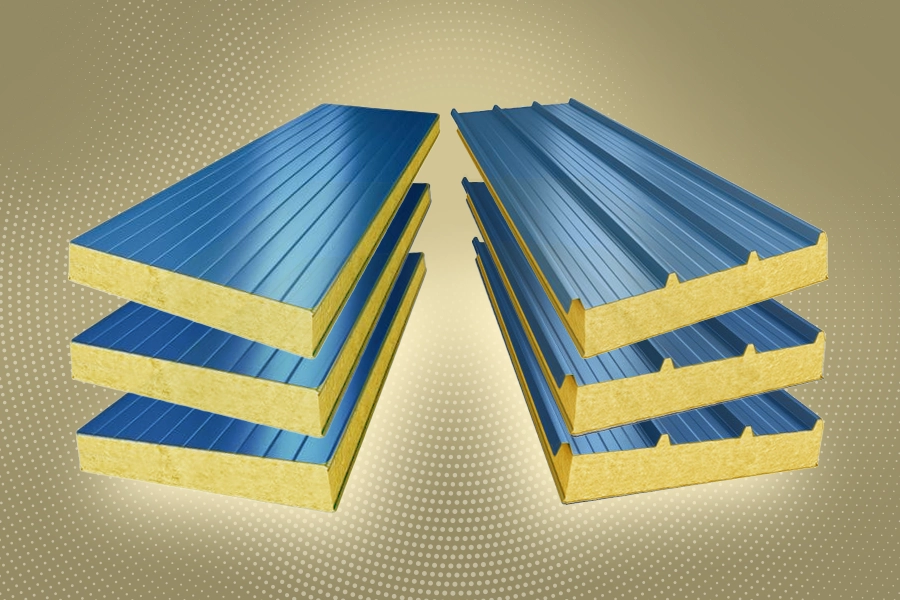

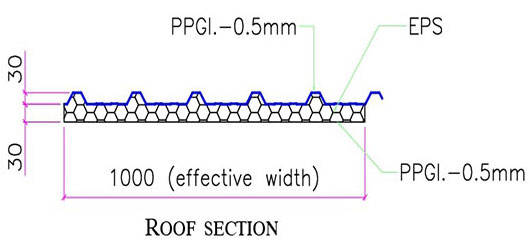

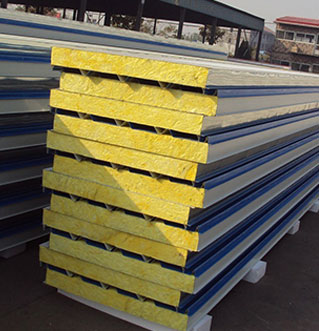

Rockwool panels are well known in the industry for fire-resistant properties. They are made from stone wool which forms the core insulation panel. This layer is sandwiched between two outer metal sheets.

The stone wool insulation material is compressed into dual-density rigid boards. The exterior surface of the insulation board is compressed more than the rest of the board. So the outer surface is stronger and offers higher compressive strength in the insulation system.

Rockwool Panel Features

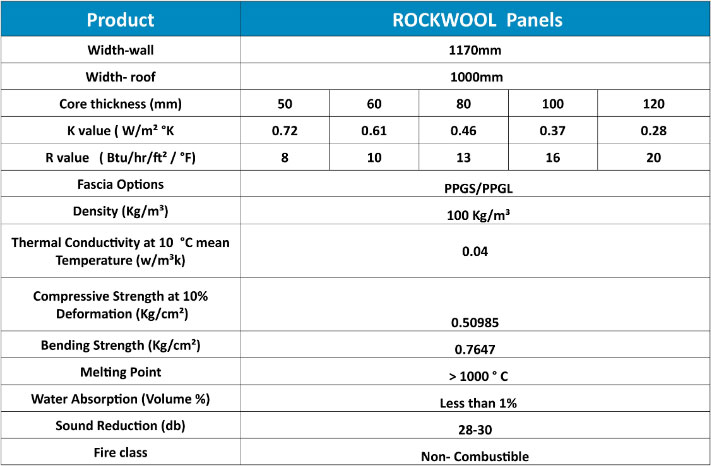

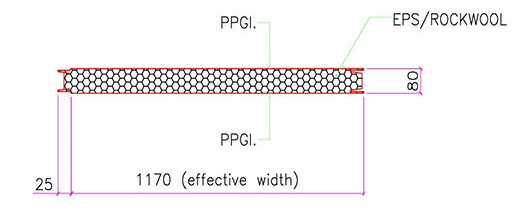

Technical Details

Applications from innovative panel solutions

Our Rockwool Panels find application in a wide range of buildings and structures as below:

- Control rooms

- Turbine-Generator Buildings

- Power project buildings

- Drivers and ovens insulation

- Compressor rooms

- Acoustic rooms

- HVAC ducting

- Fire safety applications

Benefits from EPACK Prefab

Best fire rated panels: Our Rockwool Insulation Panels are certified for non-combustibility as they never cause or spread a fire. The Rockwool panels act as fire protection layers and are best known for this quality.

Improved insulation: Rockwool Sandwich Panels provide an excellent and effective protection against heat and cold.

Its insulation properties are due to natural air entrapped within and it therefore does not emit obnoxious gases or blowing agents like HCFC, Pentane and CO2.

Supreme acoustic properties: Rockwool acoustic foam panels have a natural open cell structure making them ideal for absorbing, containing and regulating noise.

Higher sustainability: Being sustainable and durable, sound proof walls offer lifetime insulation benefits. They require very low maintenance and are environment friendly, thus contributing towards green construction.

For Further Inquiries Call

(+91) 959 948 5789If you have a query, please feel free to call us. Our team will assist you.

Manufacturing Excellence Delivered at your Doorstep

Tell us your requirements. We will execute it to Perfection!

Other Sandwich Panels We Manufacture

Besides Rockwool Panels, we also manufacture EPS, PUF and Glasswool insulated sandwich panels.

Feel free to reach out if you have a requirement.

PUF Panels

EPS Panels

Glass Wool Panel

Common Questions

-

01 What are Rockwool panels used for?

Rockwool panels are primarily used where superior fire resistance, sound insulation, and thermal control are needed—like industrial enclosures, power plants, control rooms, cold storages, and acoustic partitions.

-

02 Are Rockwool panels fireproof?

Yes. Rockwool is non-combustible and provides excellent fire resistance, making these panels ideal for fire-rated wall and roof applications.

-

03 What is the thermal and acoustic performance of Rockwool panels?

Rockwool panels provide outstanding thermal insulation and superior acoustic performance, which is why they’re commonly used in sound-sensitive and temperature-controlled environments.

-

04 What are the available thicknesses for Rockwool panels?

EPACK offers Rockwool panels in various thickness options ranging from 50mm to 150mm, customizable based on insulation needs.

-

05 Are Rockwool panels suitable for outdoor installations?

Absolutely. These panels are water-resistant, weatherproof, and corrosion-resistant, making them ideal for exterior applications.

-

06 Do Rockwool panels meet compliance or certification standards?

Yes, EPACK’s Rockwool panels comply with national building codes and fire safety standards. Certifications like BMTPC or GRIHA can also support green building needs.

-

07 Can I customize the panel size and coating?

Yes, EPACK Prefab provides custom options for panel dimensions, finishes (PPGI, PPGL, SS), and even color preferences.

-

08 Are these panels easy to install and maintain?

Yes. Rockwool panels are designed for quick installation and require minimal maintenance over their long lifecycle.