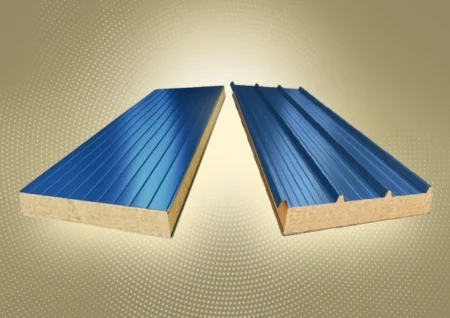

EPACK Prefab is one of the trusted sandwich panel manufacturer and supplier in Chhindwara, delivering innovative building solutions that combine environmental performance, safety, and cost-effectiveness. Our advanced manufacturing network includes three state-of-the-art plants at Greater Noida (Uttar Pradesh), Ghilot (Rajasthan), and Mambattu (Andhra Pradesh, near Sri City)—ensuring consistent quality and nationwide coverage.

For all Chhindwara projects, material supply is managed from our Greater Noida (Uttar Pradesh) facility, ensuring rapid delivery, logistics efficiency, and reliable service for construction sites across Madhya Pradesh and central India.