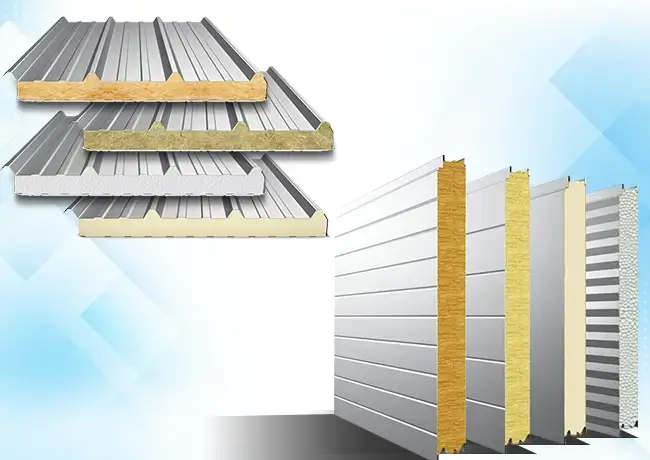

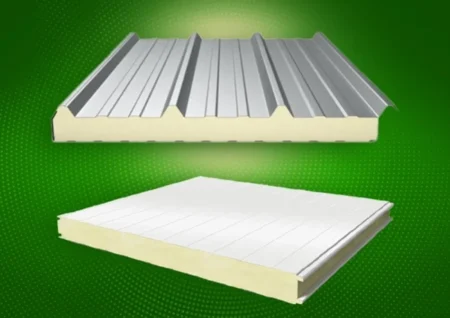

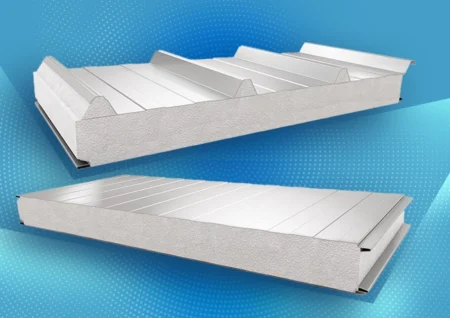

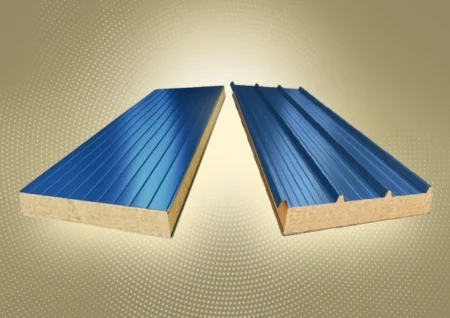

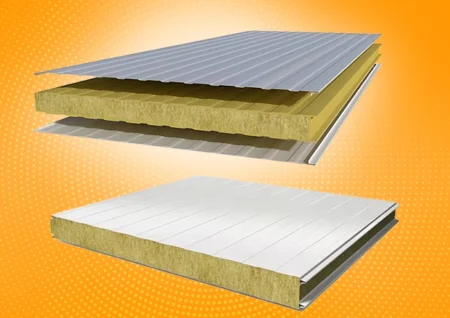

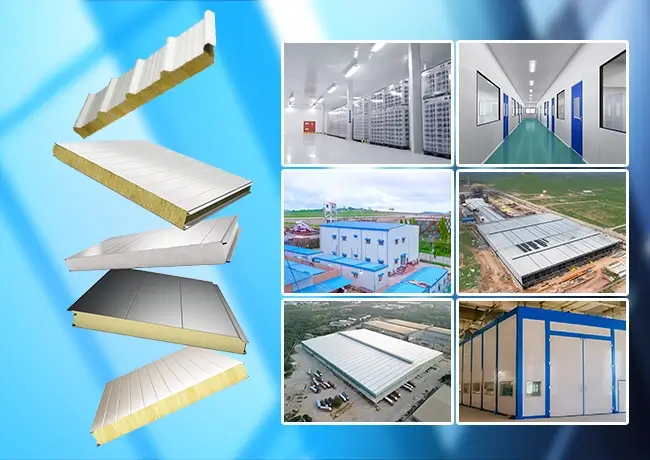

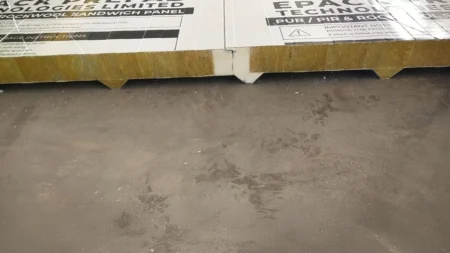

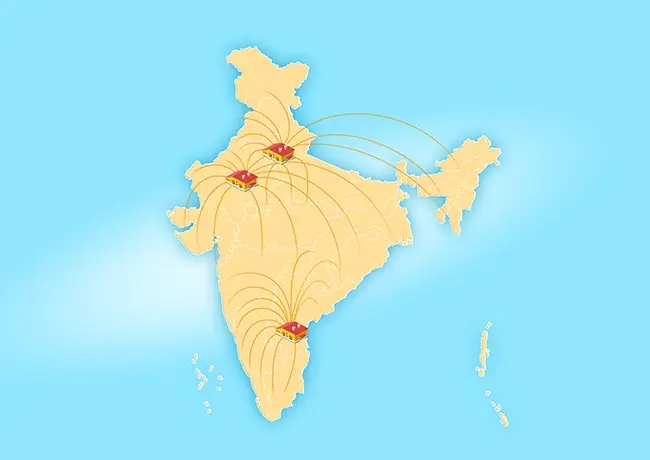

EPACK Prefab is one of India’s leading sandwich panel manufacturers, offering a wide range of insulated panels engineered for thermal efficiency, structural durability, and quick installation. With both continuous and discontinuous line production capabilities, we ensure consistent quality, precision, and flexibility across large-scale and custom projects alike.

Our sandwich panels are trusted for use in diverse applications including warehouses, cold storage units, agro facilities, pharma structures, industrial buildings, and commercial enclosures.