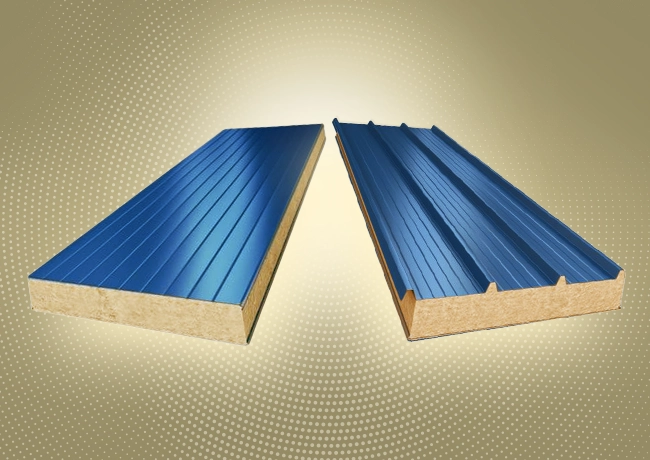

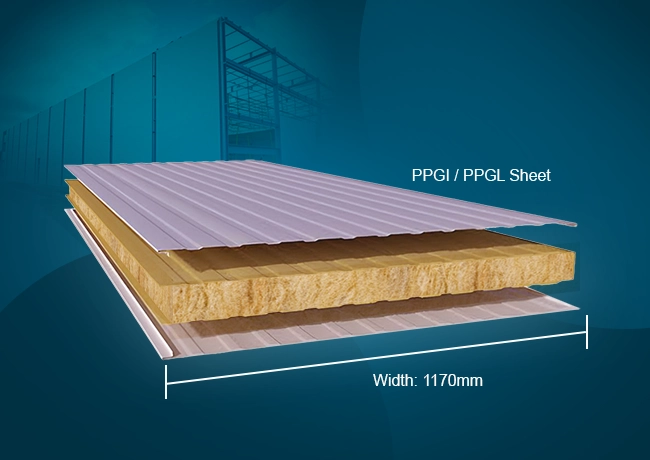

EPACK Prefab’s Rockwool Sandwich Panels are engineered for environments where fire safety, acoustic comfort, and thermal efficiency are critical. With a core of stone wool (rockwool) sandwiched between durable metal sheets, these panels offer superior resistance to fire, outstanding sound absorption, and stable thermal performance — ideal for industrial, commercial, and specialized applications.

Key Features & Technical Specifications

- Core Material: Non-combustible stone wool (rockwool) → high fire rating

- Thermal Performance: K-values around 0.024-0.080 W/m·K depending on thickness & density

- Thickness Options: Typically 50 mm to 150 mm (customizable)

- Widths / Profiles: Standard widths (e.g. 1000-1150 mm), metal facings (PPGI / PPGL / Galvalume etc.), Standard Rib / Micro-Rib or smooth finishes

- Compressive / Flexural Strength: Designed to meet structural requirements; surface compression zones for durability

- Acoustic Performance: Excellent sound absorption & noise dampening (specific decibel reduction values as per lab tests)

- Fire Safety: Non-combustible core that remains stable under heat; helps in fire-rated walls/roof applications

- Moisture / Weather Resistance: Proper facing and seals to resist water ingress; stable under temperature/humidity swings

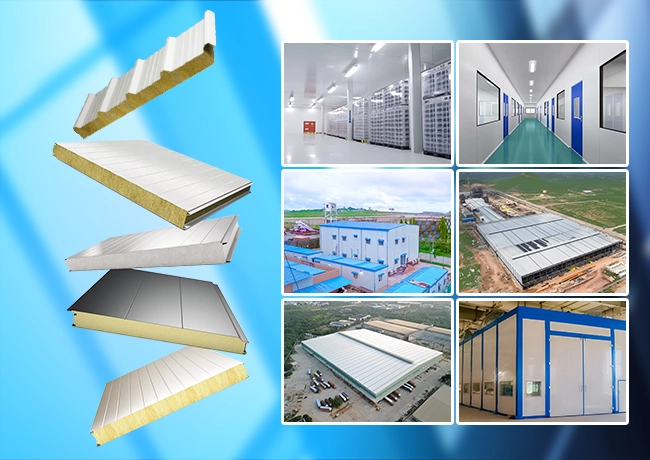

Applications

Rockwool panels are especially suited for:

- Fire-rated walls and roofs in industrial & commercial buildings

- Control rooms, turbine / generator enclosures

- Acoustic rooms, auditoriums, sound-sensitive partitions

- HVAC duct enclosures & compressor / generator rooms

- Cold storage where sound + fire safety matter

- Clean rooms / labs requiring hygienic and fire safe walls

Rockwool Panel Types & Applications

Comparison: Rockwool vs Other Panel Cores

| Property | Rockwool Panels | PUF / PIR Panels | EPS Panels |

|---|---|---|---|

| Fire Resistance | Very high, non-combustible | Good (varies by core) | Lower |

| Sound / Acoustic Performance | Excellent | Moderate | Lower to moderate |

| Thermal Insulation per Thickness | High | Very high (for thinner sections) | Moderate, needs thicker panels |

| Cost | Higher than EPS, often comparable to or slightly more than PUF depending on spec | Varies | Lower cost |

| Weight | Heavier | Lighter | Very light |

| Handling / Installation | Needs careful handling, more labor due to weight | Easier | Easiest |

Available Customizations

- Panel Lengths: As per project requirements

- Sheet Options: PPGI / PPGL / SS / Aluminium

- Surface Finish: Plain / Corrugated

- Width Customization: Available for bulk orders

Get a Quote for Rockwool Panels

For fire-rated, soundproof, and thermally stable panel solutions, contact EPACK Prefab. We deliver high-quality Rockwool panels tailored to your project requirements.

Frequently Asked Questions

Rockwool Sandwich Panels are high-performance building panels consisting of a rigid core of stone wool (made from molten basalt rock) bonded between two durable metal facings. They are designed to provide exceptional fire resistance, thermal insulation, and acoustic control in a single, easy-to-install product.

EPACK Rockwool panels achieve a high fire rating. The non-combustible stone wool core remains stable at temperatures exceeding 1000°C, preventing flame spread and protecting structural integrity during fire incidents.

Yes, they are excellent for soundproofing. The dense, fibrous structure of the stone wool core is highly effective at absorbing sound waves and reducing noise transmission. This makes them ideal for acoustic enclosures, studios, offices, and industrial facilities in noisy areas.

Their primary use is in applications where safety and noise are critical:

- Fire-rated Walls & Partitions in buildings, factories, and public spaces.

- Acoustic Enclosures for generators, HVAC units, and machinery.

- Pharmaceutical & Food Processing Plants requiring hygiene and fire safety.

- Commercial & Industrial Roofing and Cladding for enhanced safety.

- HVAC & Duct Insulation due to their fire resistance and thermal properties.

The key benefits are:

- Ultimate Fire Safety: Best-in-class, non-combustible protection.

- Superior Acoustic Performance: Excellent for noise reduction.

- Moisture Resistance: Hydrophobic core repels water, preventing mold.

- Thermal Insulation: Provides stable and effective thermal efficiency.

- Durability: Resists corrosion, pests, and maintains performance long-term.

EPACK Prefab offers Rockwool panels in a range of thicknesses (50 mm, 60 mm, 80 mm, 100 mm, 120 mm, and 150 mm) and densities to meet specific fire resistance, acoustic, and thermal requirements for different projects.

Yes. Rockwool is made from abundant natural stone (basalt) and recycled content. It is fully recyclable at the end of its long life. Most importantly, its superior insulation properties significantly reduce a building’s energy consumption and carbon footprint over time.

Absolutely. While PUF panels are often the first choice for maximum thermal efficiency, Rockwool is an excellent alternative for cold storage where fire safety is a major concern. Its hydrophobic nature also prevents moisture buildup, which is crucial in cold environments.

Our panels are manufactured in ISO-certified facilities using advanced continuous line & technology. We implement rigorous quality control at every stage, from raw material selection to final lamination, ensuring consistent density, precise dimensions, and guaranteed performance that meets international standards.

Choosing EPACK means choosing a partner, not just a product. We offer:

- High-Quality, Certified Products

- Customizable Solutions (thickness, facing, profile)

- Expert Technical Support from design to installation

- Pan-India Supply Chain for reliable and timely delivery