At EPACK Prefab, we offer state-of-the-art insulated panels specifically designed for cold room and temperature-controlled environments. These panels ensure exceptional thermal insulation, fire safety, and energy efficiency, making them ideal for cold storages, food processing units, pharmaceutical facilities, and laboratories.

Types of Cold Room Panels We Offer

We provide a wide variety of insulated sandwich panels based on different grooves and insulation cores:

Cold Wall Panel (Double Groove)

Ideal for cold storage walls and ceilings.

- Core Options: PIR / PUR / Rockwool

- Thickness (mm):

- PIR/PUR: 60, 80, 100, 120, 150

- Rockwool: 80, 100

- Width: 1100mm (Also available in 950mm for large orders)

- Key Benefits:

- High compressive strength

- Fire-resistant performance

- Moisture & airtight sealing

- Foam-to-foam gap: 0.00 for superior insulation

Wall Panel (Single Groove)

Versatile for partitions, facades, and cladding.

- Core Options: PIR / PUR / Rockwool

- Thickness (mm):

- PIR/PUR: 30, 40, 50, 60

- Rockwool: 50

- Width: 1150mm (Also available in 1000mm for large orders)

Why Choose EPACK Cold Room Panels?

- Superior Thermal Efficiency

Industry-leading K-values for minimal energy loss. - Eco-Friendly Insulation

Zero ODP (ozone depletion potential), CFC & HCFC free. - Excellent Fire Resistance

Fire-retardant and self-extinguishing panels with certified performance. - Faster Installation

Lightweight panels with tongue & groove joints ensure quick and secure installation. - Durable and Weather Resistant

Built for long-term structural performance in demanding environments.

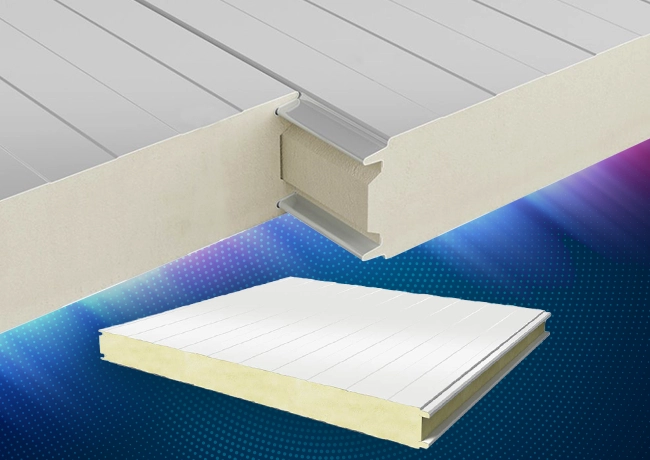

Panel Construction & Materials

Each panel is constructed using a high-quality core material (PIR, PUR, Rockwool) sandwiched between premium outer sheets (PPGI/PPGL/Stainless Steel/Aluminum). The precision-engineered tongue-and-groove jointing system ensures maximum airtightness.

| Material Options | Outer/Inner Sheet |

| Pre-Painted Galvanized Iron (PPGI & PPGL) | Standard |

| Stainless Steel (SS) | On Request |

| Aluminium | On Request |

Technical Performance Summary

| Property | PIR Panel | PUR Panel | Rockwool Panel |

| Thermal Conductivity (K) | 0.023 W/m·K | 0.023 W/m·K | 0.04 W/m·K |

| Compressive Strength | 2.1 kg/cm² | 2.1 kg/cm² | 0.3 kg/cm² |

| Fire Resistance | Excellent | Excellent | Non-Combustible |

| Water Absorption | 0.2% | 0.2% | <1% |

| Closed Cell Content | 90–95% | 90–95% | Open Structure |

Applications

- Food processing industry

- Cold storages

- Clean Rooms

- Telecom Shelters

- Fruit & vegetable storage

Download Technical Catalogue

Common queries

Cold Room Panels are used in temperature-controlled environments such as cold storages, frozen food warehouses, pharmaceutical storage units, clean rooms, and processing plants. They ensure optimal thermal insulation and help maintain a consistent internal temperature.

EPACK Cold Room Panels are manufactured using high-performance core materials like PUF (Polyurethane Foam) and PIR (Polyisocyanurate Foam), enclosed between pre-painted galvanized steel sheets for superior insulation, strength, and durability.

Our Cold Wall Panels (Double Groove) are available in the following specifications:

- Thickness: 60mm, 80mm, 100mm, 120mm, 150mm

- Standard Width: 1100m

- Optional Width: 950mm (for large volume orders)

Yes, EPACK Cold Room Panels are fire-retardant and meet safety standards. PIR core panels, in particular, offer enhanced fire resistance with low flame spread and self-extinguishing properties.

Absolutely. EPACK Cold Room Panels offer very low thermal conductivity (0.023 W/m·K for PUF/PIR), which significantly reduces energy consumption for refrigeration and cooling, making them highly energy-efficient.

Yes, the same Cold Wall Panels are often used in clean rooms and pharma-grade environments due to their airtight installation, hygienic surface, and thermal stability.

Yes. The panels are designed with a tongue-and-groove system and foam-to-foam joints, ensuring fast, precise, and leak-proof installation—saving time and labor costs on-site.

Yes, we can customize panel thickness and width based on your project requirements and quantity. Standard customization includes width adjustments (950mm on request).

EPACK provides end-to-end solutions, including manufacturing, delivery, and installation assistance through our nationwide network and expert teams.