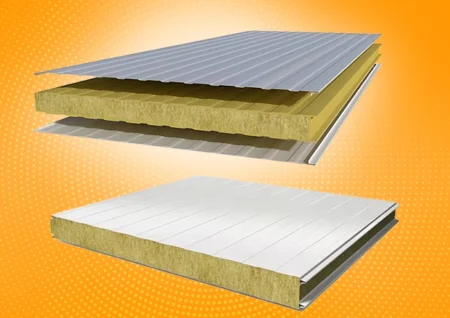

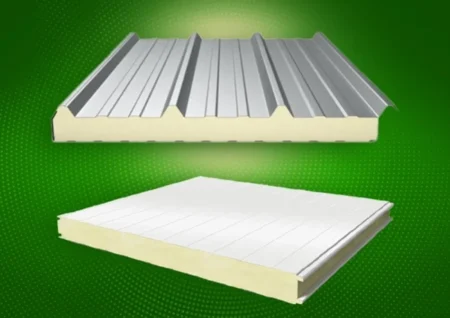

Thermal insulation is a construction process aimed at reducing transmission or conductivity of heat between interior and exterior building environments. This facilitates an enhanced possibility of energy savings and longevity of heat or cold retention indoors. The use of EPS sandwich panels for buildings in Muktsar makes possible guaranteed improvement in overall cost savings as well as better structural quality owing to superlative grade material use.

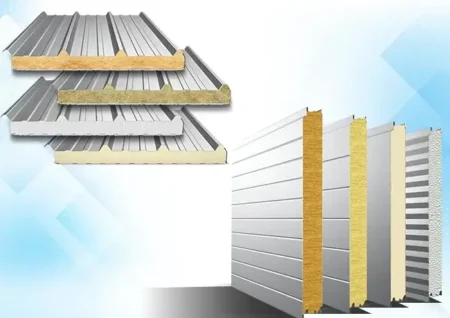

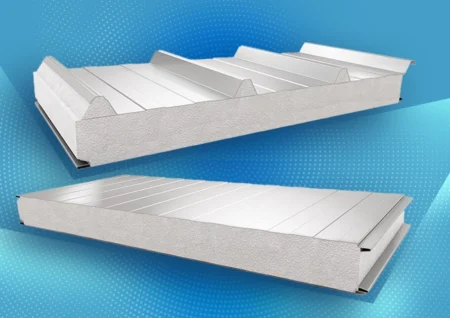

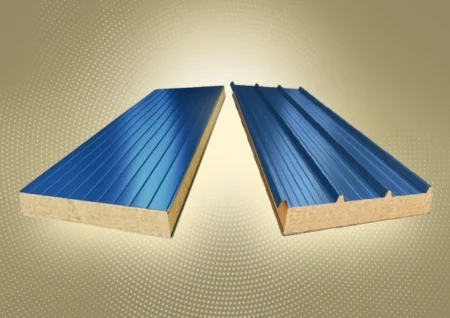

These durable envelops also safeguard buildings from all kinds of wither conditions and physical as well as chemical action. EPACK prefabricated sandwich panels are designed in accordance with stringent ISO standards which is a hallmark of performance, quality and safety. The company maintains a world class production infrastructure for its sandwich PUF roofing panels which feature dual layered metal sheets sandwiching core materials.