Cold storage facilities are a backbone of modern supply chains, enabling safe storage of temperature-sensitive products across industries. From agriculture and food processing to pharmaceuticals and e-commerce, the demand for efficient, scalable, and energy-saving cold storages is growing rapidly.

This is where Pre-Engineered Buildings (PEB) and prefab cold storage solutions offer unmatched advantages in speed, insulation performance, and long-term cost efficiency.

1. Chilled Cold Storage (0°C to +10°C)

Chilled cold storages maintain temperatures above freezing to preserve freshness and slow spoilage.

Industries Using Chilled Cold Storage

- Agriculture & horticulture

- Dairy industry

- Food & beverage sector

- Pharmaceutical distribution

- Retail & supermarkets

PEB Advantage

PEB cold storages provide large, column-free spaces and insulated sandwich panels that ensure uniform cooling and energy efficiency.

2. Frozen Cold Storage (–18°C to –40°C)

Designed for long-term preservation by halting microbial activity through sub-zero temperatures.

Industries Using Frozen Cold Storage

- Meat & poultry processing

- Seafood industry

- Frozen food manufacturers

- FMCG companies

- Export-oriented food businesses

PEB Advantage

Prefab structures support high insulation thickness, vapor barriers, and refrigeration integration—ideal for deep-freeze environments.

3. Blast Freezer / Deep Freezer Cold Storage (–30°C to –45°C)

Blast freezers rapidly freeze products to retain texture, nutrition, and appearance.

Industries Using Blast Freezers

- Seafood export units

- Meat processing plants

- Bakery & confectionery units

- Ready-to-eat food manufacturers

PEB Advantage

PEB buildings easily accommodate heavy refrigeration systems and floor loads, making them ideal for blast freezing operations.

4. Controlled Atmosphere (CA) Cold Storage

CA cold storage controls oxygen, carbon dioxide, and humidity to slow down fruit ripening.

Industries Using CA Cold Storage

- Apple & fruit growers

- Agri-export companies

- Horticulture cooperatives

PEB Advantage

PEB cold storages ensure airtight construction and precise panel joints essential for maintaining controlled atmospheres.

5. Modified Atmosphere (MA) Cold Storage

Uses modified gas composition via packaging or controlled ventilation systems.

Industries Using MA Cold Storage

- Fresh produce suppliers

- Food packaging companies

- Floriculture industry

PEB Advantage

Prefab structures offer layout flexibility and modular chambers, making MA systems easy to implement and expand.

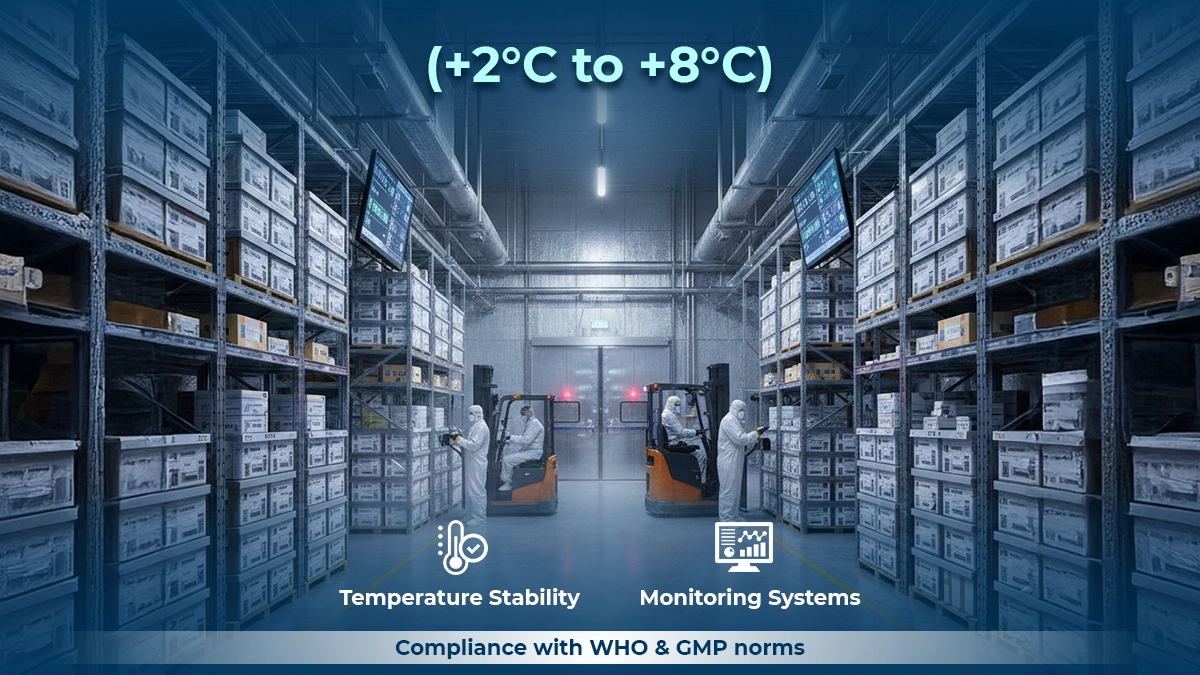

6. Pharmaceutical Cold Storage (+2°C to +8°C)

Requires highly controlled temperatures with backup systems and regulatory compliance.

Industries Using Pharma Cold Storage

- Pharmaceutical manufacturers

- Hospitals & healthcare networks

- Vaccine manufacturers

- Biotechnology companies

PEB Advantage

PEB cold storages ensure temperature stability, monitoring systems, and compliance with WHO & GMP norms.

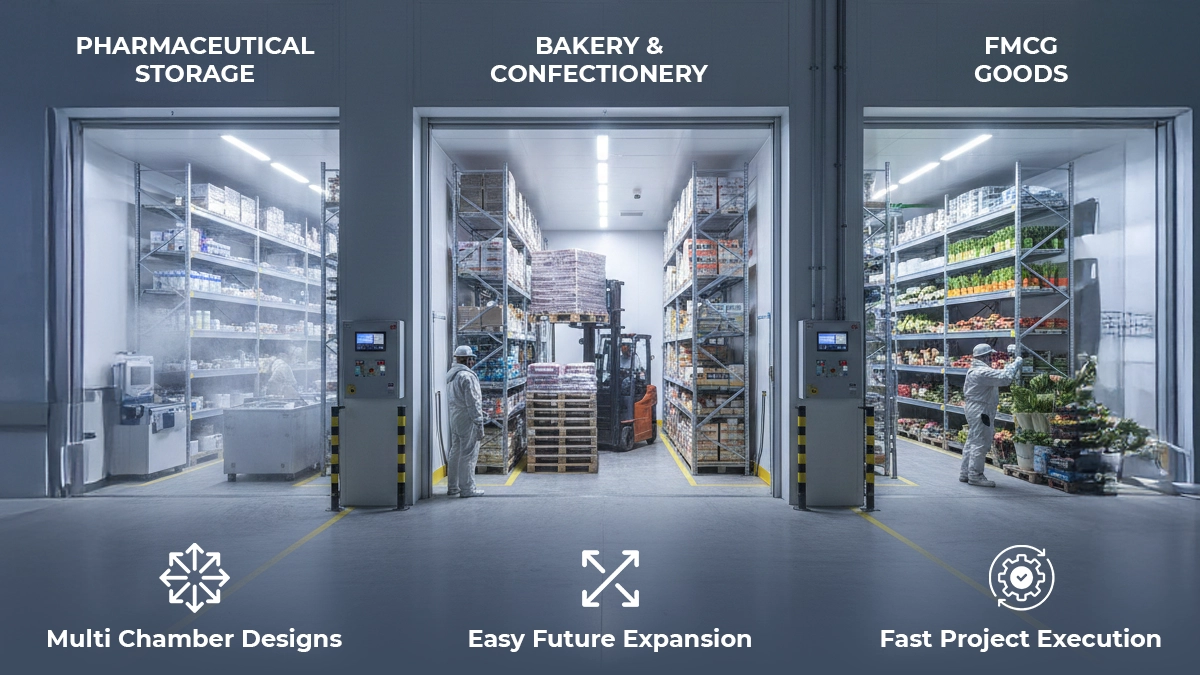

7. Multi-Temperature Cold Storage Facilities

Facilities with multiple chambers operating at different temperatures under one roof.

Industries Using Multi-Temperature Cold Storage

- Cold chain logistics companies

- E-commerce grocery platforms

- Food distribution centers

- Third-party logistics (3PL) providers

PEB Advantage

PEB buildings allow multi-chamber designs, easy future expansion, and fast project execution.

Why PEB / Prefab Cold Storage Is the Preferred Choice Across Industries

PEB and prefab cold storage buildings offer:

- Faster construction timelines

- Excellent thermal insulation using PUF/EPS panels

- Lower energy and operational costs

- Modular and scalable design

- Long-term durability and low maintenance

These benefits make PEB cold storage facilities ideal for India’s rapidly expanding cold chain infrastructure.

Conclusion

Different industries require different types of cold storage facilities—but all demand reliability, efficiency, and scalability. When combined with PEB or prefab construction, cold storages become future-ready assets that support business growth while reducing operational costs.

Investing in PEB cold storage solutions ensures faster delivery, better temperature control, and long-term sustainability.