Introduction

When establishing a business in India, choosing the right facility for operations is crucial. Two common methods stand out: Pre-Engineered Buildings (PEBs) and traditional construction methods (RCC and brick-mortar structures).

This blog compares both approaches to help businesses make informed decisions. Let’s explore why PEB solutions are gaining popularity in India’s commercial and industrial sectors.

Understanding Pre-Engineered Buildings (PEBs)

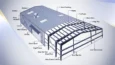

Pre-engineered buildings (PEBs) are steel structures designed and fabricated off-site before being assembled at the construction site. This modular approach ensures:

✔ Faster construction

✔ Cost-effectiveness

✔ Design flexibility

✔ Minimal material wastage

✔ Structural strength

Several top Pre-Engineered Building (PEB) manufacturers and PEB Suppliers in India, like EPACK Prefab, specialize in creating durable PEB solutions for warehouses, industrial sheds, airports, and commercial buildings.

Understanding Traditional Construction

Traditional construction involves building structures on-site from scratch, using materials like concrete, bricks, and steel. While this has been the norm for decades, it has several drawbacks:

⚠ Time-consuming – dependent on labour and weather conditions.

⚠ Higher costs – requires more labour and materials.

⚠ Limited flexibility – modifications are difficult.

⚠ More waste – generates construction debris.

PEBs vs. Traditional RCC Construction: A Detailed Comparison

| Feature | Pre-Engineered Buildings (PEBs) | Traditional Construction (RCC) |

|---|---|---|

| Speed of Construction | 50% faster; prefabricated components reduce assembly time. | Slower; labor-intensive, weather-dependent delays. |

| Cost-Effectiveness | More affordable; minimizes labour & material waste. | More expensive due to longer timelines & high labor needs. |

| Design Flexibility | Easily customizable & scalable. | Rigid design; modifications are costly. |

| Durability & Strength | Steel structures withstand harsh weather & require less maintenance. | Brick-mortar structures need higher maintenance over time. |

| Environmental Impact | Sustainable; minimal waste, steel is recyclable. ♻ | Generates excessive waste, larger carbon footprint. |

| Application Suitability | Ideal for warehouses, factories, and commercial spaces. ✅ | Better for residential projects. 🏡 |

Speed of Construction

✅ PEBs: Since pre-engineered components are manufactured off-site, on-site assembly is much quicker, reducing overall project timelines.

❌ Traditional Construction: Relies heavily on manual labour and weather conditions, which can lead to delays.

Cost-Effectiveness

✅ PEBs: Reduced material wastage and labour costs make PEB a budget-friendly option. The precise engineering process ensures cost savings.

❌ Traditional Construction: Requires more raw materials and longer timelines, leading to higher labour costs and budget overruns.

Design Flexibility

✅ PEBs: Highly flexible designs—customizable for large industrial spaces, warehouses, and factories.

❌ Traditional Construction: Modifying RCC structures post-construction is costly and time-consuming.

Structural Strength & Durability

✅ PEBs: Built with high-quality steel, making them durable against earthquakes, heavy winds, and harsh climates.

❌ Traditional Construction: Brick and concrete buildings degrade over time, requiring more maintenance.

Environmental Impact

✅ PEBs: Eco-friendly construction – steel is 100% recyclable, and fabrication produces minimal waste.

❌ Traditional Construction: High material wastage – excessive use of cement, bricks, and wood increases environmental pollution.

Industrial Applications

✅ PEBs are ideal for:

- Warehouses & logistics hubs

- Factory sheds & industrial plants

- Multi-storey office buildings

- Cold storage units

- Commercial showrooms

❌ Traditional Construction is better suited for:

- Residential apartments

- Small office buildings

- Schools & hospitals

Conclusion: Why PEBs Are the Future of Construction

Pre-Engineered Buildings are the clear winners over traditional construction methods for industrial and commercial projects. They are:

✔ Faster to build

✔ More cost-effective

✔ Highly durable

✔ Environmentally sustainable

Being one of India’s top Pre-Engineered Building manufacturers, EPACK Prefab has 2517+ satisfied clients and 25+ years of expertise. We specialize in customized PEB solutions tailored to your business needs.

📧 Have a unique PEB requirement? Contact us today at enquiry@epack.in 📞 or call +91 8130444466.