As India’s industrial and infrastructure projects accelerate in 2026, the demand for energy-efficient, safe, and performance-driven insulated panels is at an all-time high. Whether it’s cold storage, warehouses, factories, clean environments, or large public infrastructure, insulated sandwich panels play a critical role in building performance.

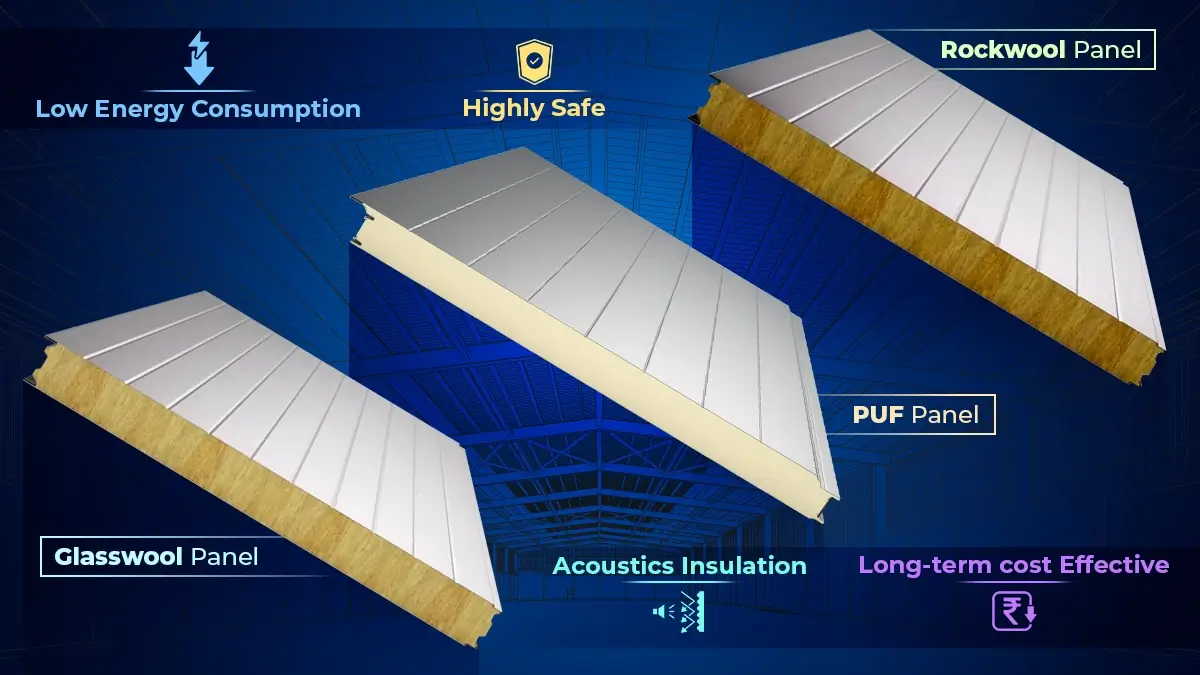

Among the most widely used insulation panels are PUF Panels, Rockwool Panels, and Glass Wool Panels. Each serves a specific purpose, and choosing the right one can significantly impact energy consumption, safety, acoustics, and long-term costs.

This buyer’s guide offers a clear, practical comparison to help you make the right decision in 2026.

Why Choosing the Right Insulated Panel Matters in 2026

Modern industrial construction demands:

- Energy efficiency amid rising power costs

- Compliance with fire and safety regulations

- Faster construction timelines

- Long-term durability with minimal maintenance

The wrong insulation choice can lead to:

- High operational costs

- Safety risks

- Reduced building lifespan

That’s why understanding the difference between PUF, Rockwool, and Glass Wool panels is essential.

Overview: PUF vs Rockwool vs Glass Wool Panels

| Parameter | PUF Panels | Rockwool Panels | Glass Wool Panels |

| Core Material | Polyurethane Foam | Mineral Wool (Rockwool) | Glass Fibers |

| Thermal Insulation | ⭐⭐⭐⭐⭐ Excellent | ⭐⭐⭐ Moderate | ⭐⭐⭐ Moderate |

| Fire Resistance | Good (Flame-retardant) | ⭐⭐⭐⭐⭐ Excellent (Non-combustible) | ⭐⭐⭐⭐ Very Good |

| Acoustic Performance | Moderate | ⭐⭐⭐⭐⭐ Excellent | ⭐⭐⭐⭐⭐ Excellent |

| Density | Low (~40 kg/m³) | High (~100–120 kg/m³) | Medium (~16–48 kg/m³) |

| Weight | Lightweight | Heavy | Lightweight |

| Moisture Resistance | ⭐⭐⭐⭐⭐ Excellent | Moderate | Moderate |

| Best Suited For | Cold storage, cold rooms | Fire & sound-critical zones | Acoustic enclosures, offices |

Understanding Each Panel Type in Detail

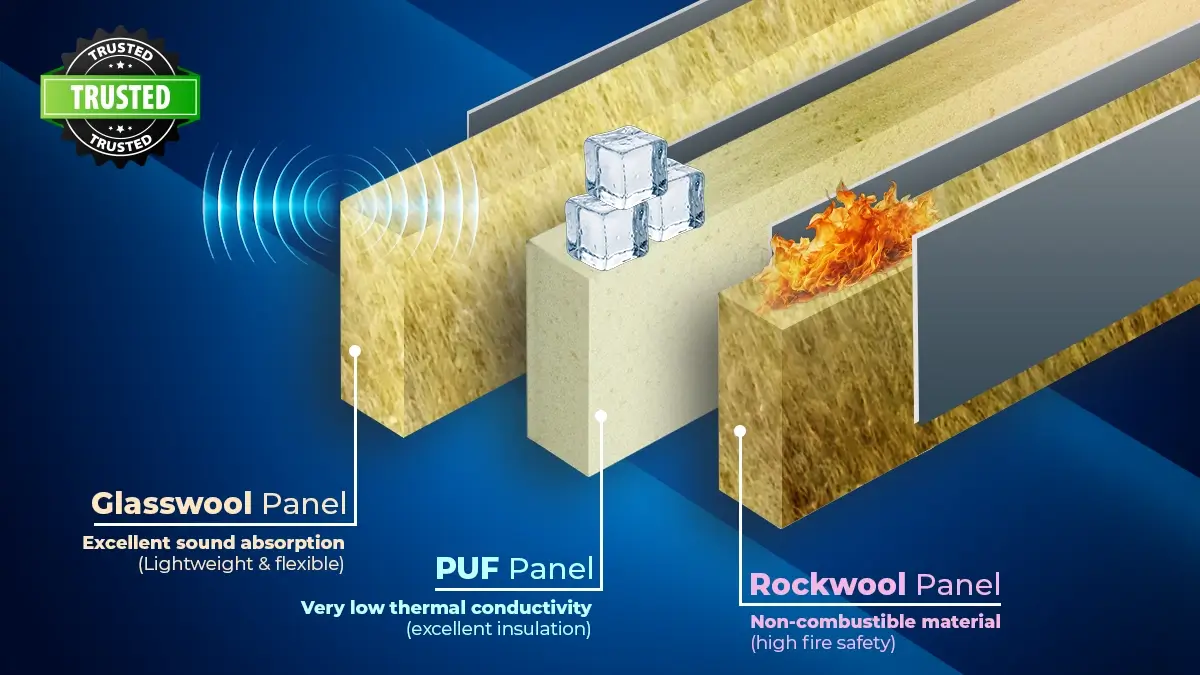

1. PUF (Polyurethane Foam) Sandwich Panels

PUF panels are the most energy-efficient insulation panels used in industrial construction today.

Key Advantages:

- Very low thermal conductivity (excellent insulation)

- Significant reduction in cooling and heating costs

- Lightweight and easy to install

- Excellent moisture resistance

- Ideal for temperature-controlled environments

Best Applications:

- Cold storage and cold rooms

- Food processing facilities

- Pharmaceutical storage

- Clean environments requiring thermal stability

PUF panels are the preferred choice where temperature control and energy savings are the top priorities.

2. Rockwool Sandwich Panels

Rockwool panels are known for their exceptional fire resistance and sound absorption.

Key Advantages:

- Non-combustible material (high fire safety)

- Excellent acoustic insulation

- High density and structural stability

- Suitable for fire-prone industrial zones

Best Applications:

- Power plants and heavy industries

- Airports, metro stations, and railway infrastructure

- Fire-rated industrial buildings

- Noise-sensitive industrial enclosures

Rockwool panels are ideal where fire safety and noise control outweigh thermal insulation needs.

3. Glass Wool Sandwich Panels

Glass wool panels strike a balance between acoustic performance, fire resistance, and cost efficiency.

Key Advantages:

- Excellent sound absorption

- Lightweight and flexible

- Good fire resistance

- Cost-effective for large-scale use

Best Applications:

- Acoustic enclosures

- Warehouses and industrial sheds

- Offices, laboratories, and institutional buildings

- Noise-sensitive commercial spaces

Glass wool panels are a smart choice when acoustics and budget optimization are key considerations.

Which Panel Should You Choose in 2026?

Choose PUF Panels if:

- You are building cold storage or cold rooms

- Energy efficiency and temperature control are critical

- Long-term operational cost savings matter

Choose Rockwool Panels if:

- Fire safety is non-negotiable

- Noise control is a priority

- The project involves heavy industrial or public infrastructure

Choose Glass Wool Panels if:

- Acoustic insulation is the main requirement

- You need a cost-effective insulation solution

- The project involves offices, enclosures, or warehouses

The Role of Advanced Panel Manufacturing in 2026

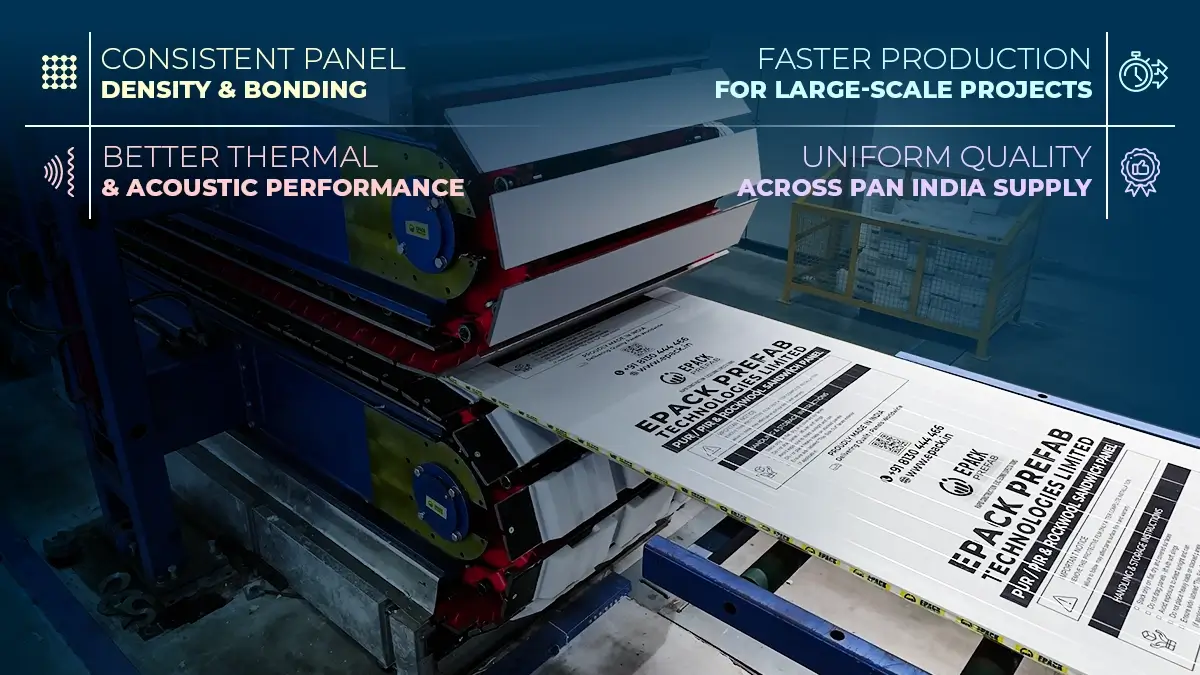

Modern insulated panels are no longer basic products. Advanced manufacturing technologies such as Continuous Panel (CP) lines ensure:

- Consistent panel density and bonding

- Better thermal and acoustic performance

- Faster production for large-scale projects

- Uniform quality across PAN India supply

This becomes especially important for projects with tight timelines and high-performance expectations.

How EPACK Prefab Supports the Right Panel Choice

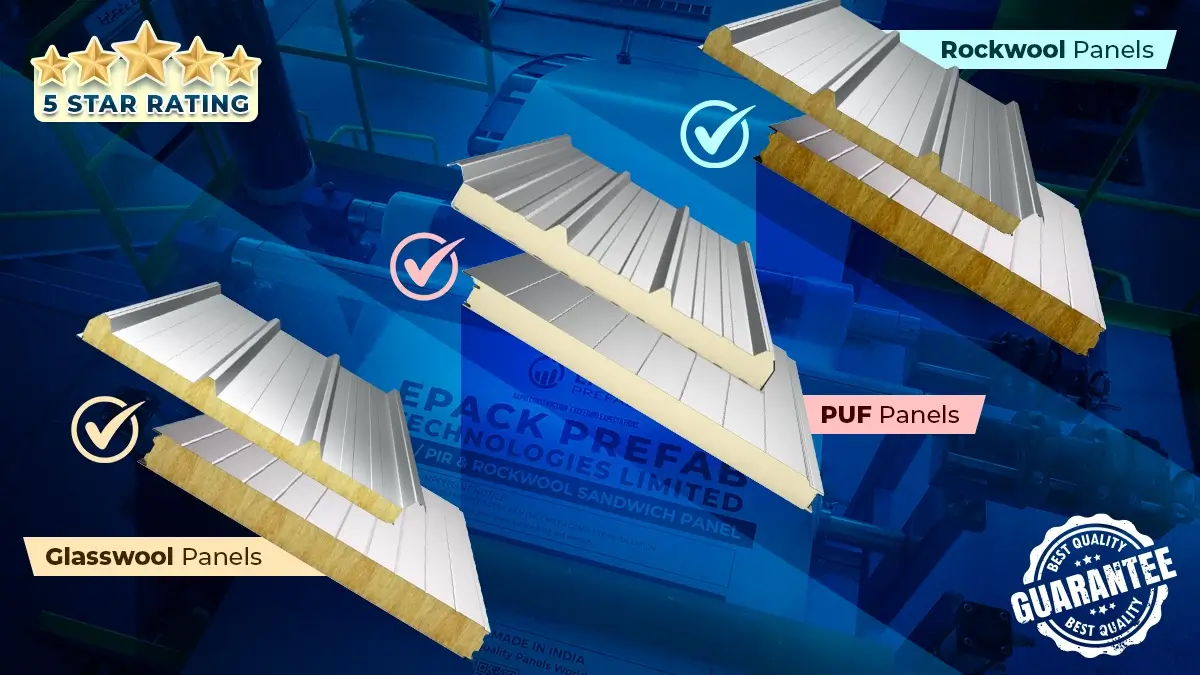

EPACK Prefab offers all three panel types—PUF, Rockwool, and Glass Wool—manufactured using advanced continuous panel lines.

With:

- 25+ years of industry experience

- Multiple manufacturing plants across India

- PAN India supply and execution capability

- End-to-end solutions for industrial and infrastructure projects

EPACK Prefab helps buyers select the right panel for the right application, not a one-size-fits-all solution.

Final Thoughts

In 2026, there is no “best” insulation panel—only the right panel for the right use case.

- PUF Panels lead in energy efficiency and cold storage

- Rockwool Panels dominate fire safety and acoustics

- Glass Wool Panels offer balanced acoustic and cost performance

Making an informed choice ensures better building performance, lower operating costs, and long-term reliability.

For expert guidance on insulated sandwich panels or bulk project requirements, connect at enquiry@epack.in or call +918130444466.