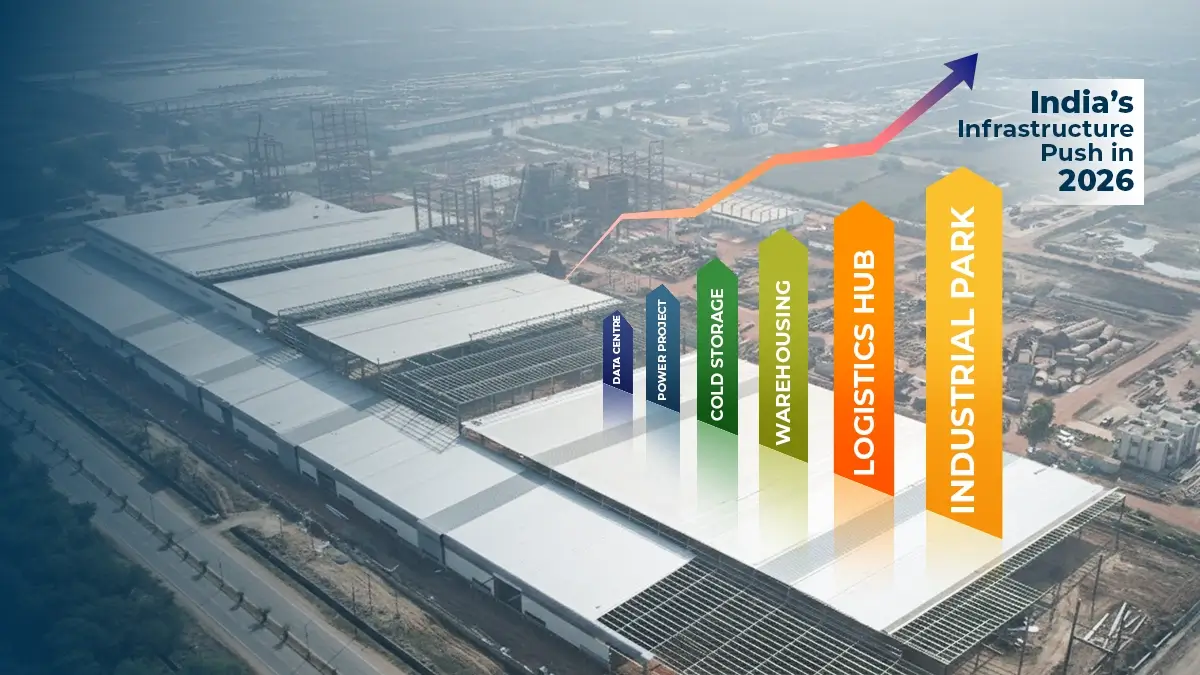

India’s industrial infrastructure is evolving faster than ever in 2026. With rapid expansion in manufacturing, logistics, renewable energy, cold chain, and heavy industries, the country needs construction solutions that are fast, scalable, cost-efficient, and future-ready.

This is where Pre-Engineered Buildings (PEB) are playing a transformative role. What was once considered an alternative construction method has now become the preferred choice for industrial infrastructure development across India.

This blog explains how PEB buildings are reshaping India’s industrial landscape in 2026 and why industries are increasingly moving away from conventional construction.

India’s Industrial Growth Demands a Smarter Construction Approach

India’s infrastructure push in 2026 is driven by:

- Expansion of manufacturing units and industrial parks

- Growth of warehousing and logistics hubs

- Rising demand for cold storage and cold rooms

- Investments in renewable energy and power projects

- Development of automobile, cement, and data centre facilities

Traditional construction methods struggle to match the speed, consistency, and efficiency required at this scale. PEB buildings address these challenges effectively.

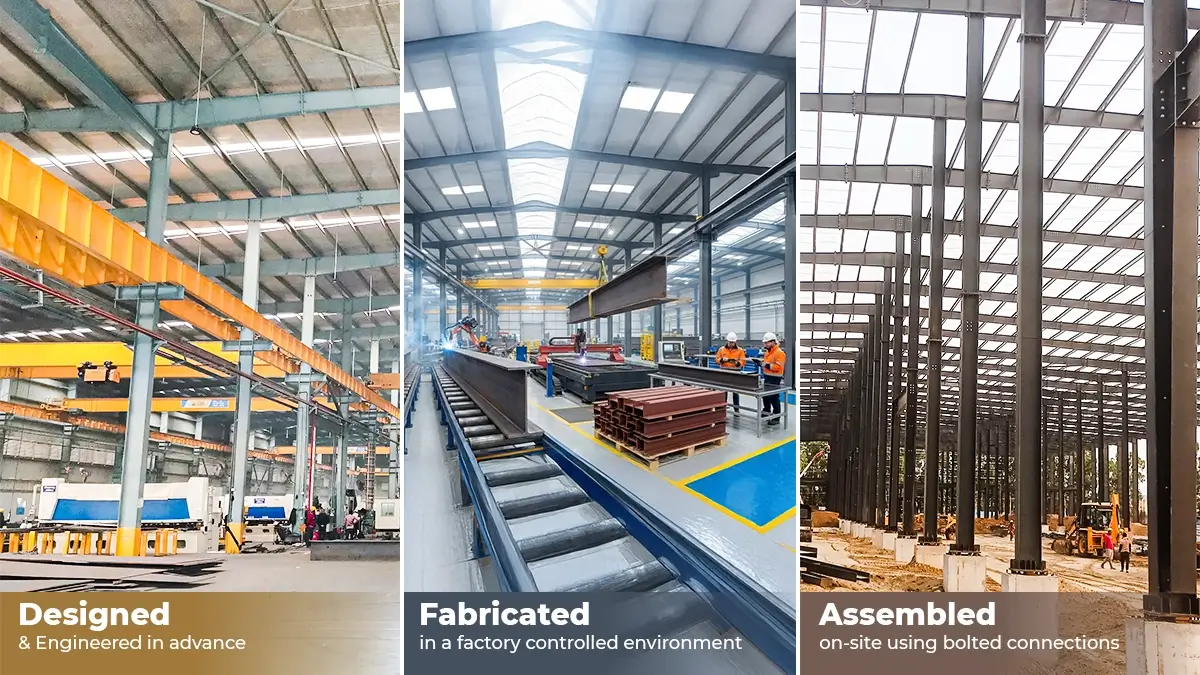

What Are PEB Buildings?

Pre-Engineered Buildings are steel structures that are:

- Designed and engineered in advance

- Fabricated in a controlled factory environment

- Assembled on-site using bolted connections

Every structural component—columns, beams, rafters, purlins—is engineered for optimal load performance, reducing unnecessary steel usage while maintaining strength and safety.

Key Ways PEB Buildings Are Transforming Industrial Infrastructure

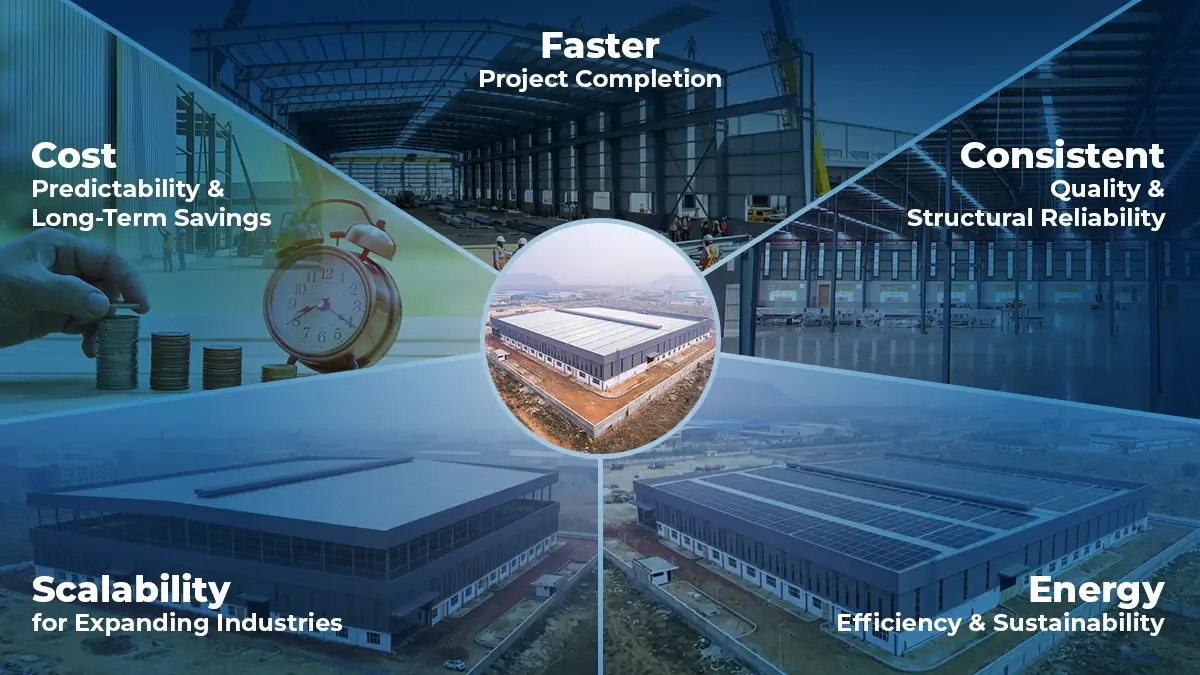

1. Faster Project Completion

Speed is critical for industrial projects where delays impact production and revenue.

PEB buildings enable:

- Parallel execution of foundation work and steel fabrication

- Faster erection compared to RCC construction

- Reduced dependency on on-site labour and weather conditions

As a result, industrial facilities can become operational 30–40% faster.

2. Cost Predictability and Long-Term Savings

One of the biggest advantages of PEB construction is cost control.

PEB buildings offer:

- Optimised steel usage through engineering design

- Minimal material wastage

- Reduced labour costs

- Lower maintenance requirements over time

This makes PEB a financially sound choice for long-term industrial investments.

3. Scalability for Expanding Industries

Industries rarely remain static. Capacity expansion is often planned in phases.

PEB buildings allow:

- Easy future expansion

- Modular extensions without shutting down operations

- Flexible layouts to accommodate new machinery or processes

This scalability is a major reason PEB is preferred for factories, warehouses, and logistics parks.

4. Energy Efficiency and Sustainability

With rising energy costs and sustainability goals, energy-efficient infrastructure is essential.

PEB buildings integrate well with:

- Insulated sandwich panels (PUF, Rockwool, Glass Wool, EPS)

- Natural lighting and ventilation solutions

- Energy-efficient roofing and wall systems

These features help reduce operational energy consumption and support greener industrial development.

5. Consistent Quality and Structural Reliability

Unlike on-site fabrication, PEB components are manufactured under strict quality control.

This ensures:

- Precision engineering

- Uniform quality across large projects

- High safety standards

- Structures designed to withstand wind, seismic, and operational loads

For industrial infrastructure, this reliability is non-negotiable.

Major Industrial Applications of PEB Buildings in 2026

PEB buildings are widely used across industrial sectors, including:

- Manufacturing Plants: Optimised layouts and heavy-load capacity

- Warehouses & Logistics Parks: Large clear spans and fast execution

- Cold Storage & Cold Rooms: Compatibility with insulated panel systems

- Renewable Energy Projects: Site infrastructure and utility buildings

- Automobile & Cement Plants: Durable, expandable industrial structures

Their versatility makes PEB buildings suitable for both greenfield and brownfield projects.

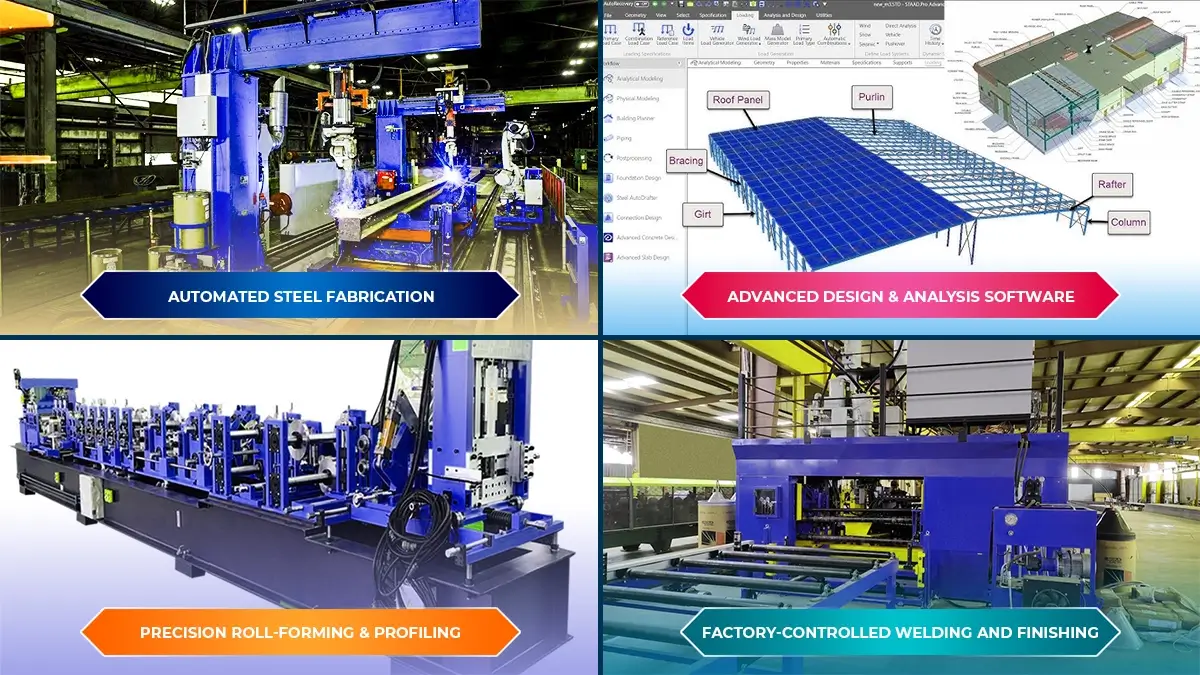

The Role of Advanced Manufacturing in Modern PEB Systems

Modern PEB construction is backed by:

- Automated steel fabrication

- Advanced design and analysis software

- Precision roll-forming and profiling

- Factory-controlled welding and finishing

These advancements ensure faster delivery, higher accuracy, and longer service life—key requirements for industrial infrastructure in 2026.

How EPACK Prefab Is Supporting India’s Industrial Transformation

EPACK Prefab has been a key contributor to India’s industrial infrastructure growth through:

- Engineered PEB solutions for diverse industrial applications

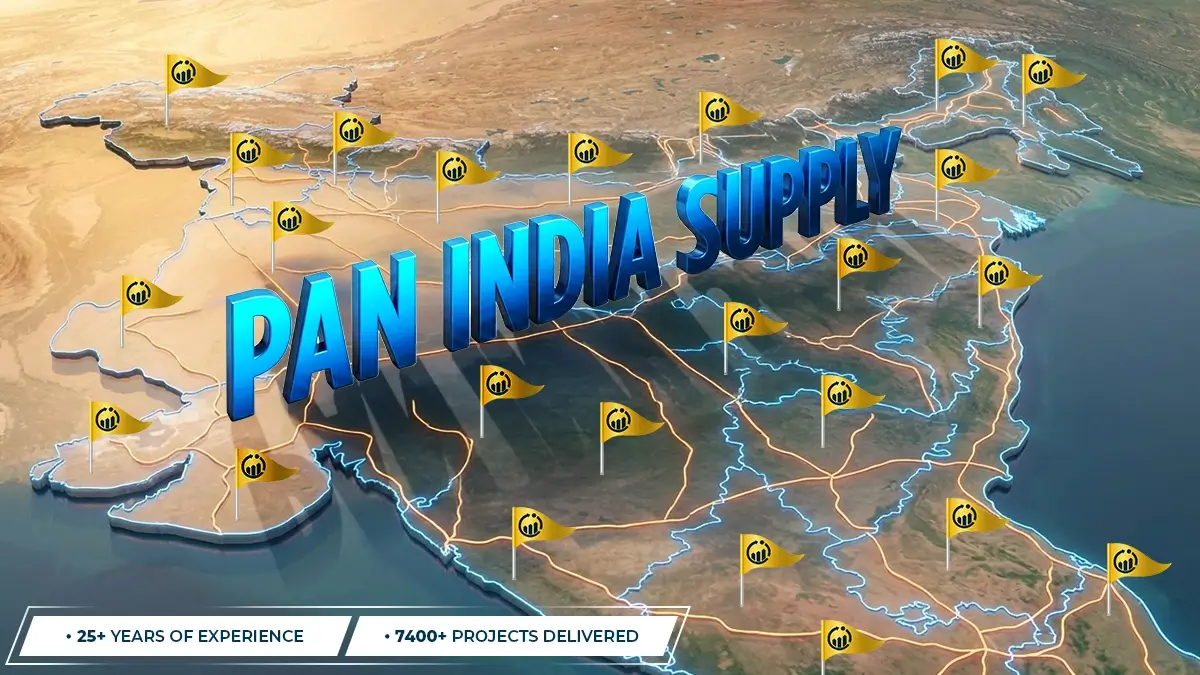

- Advanced manufacturing facilities with PAN India Supply

- Integrated solutions combining structures and insulated panels

- End-to-end support from design to delivery

With 25+ years of experience and 7400+ projects delivered, EPACK Prefab helps industries build infrastructure that is reliable, scalable, and future-ready.

PEB Buildings: The New Standard for Industrial Construction

In 2026, PEB buildings are no longer a niche solution—they are the new standard for industrial infrastructure in India.

Their ability to deliver:

- Speed

- Cost efficiency

- Design flexibility

- Energy performance

- Long-term durability

makes them indispensable for India’s industrial growth story.

Conclusion

PEB buildings are fundamentally transforming how India builds its industrial infrastructure in 2026. By combining engineering precision, faster execution, and sustainable performance, they enable industries to grow without construction bottlenecks.

As India continues its journey toward becoming a global manufacturing and logistics hub, PEB buildings will remain at the core of industrial infrastructure development.

For industrial PEB solutions or project discussions, connect at enquiry@epack.in or call +918130444466