Whether you’re developing a cold storage, industrial facility, clean room, warehouse, or any temperature-controlled building—selecting the right PUF panel supplier is one of the most important decisions for long-term success.

Your choice directly impacts:

- Energy efficiency

- Durability

- Construction speed

- Maintenance cost

- Overall project performance

With multiple suppliers in the market, the challenge is finding a partner that delivers consistent quality backed by advanced technology and reliable service.

Here are the 5 key factors to consider before finalizing a PUF panel manufacturer—along with how EPACK Prefab stands out in each category.

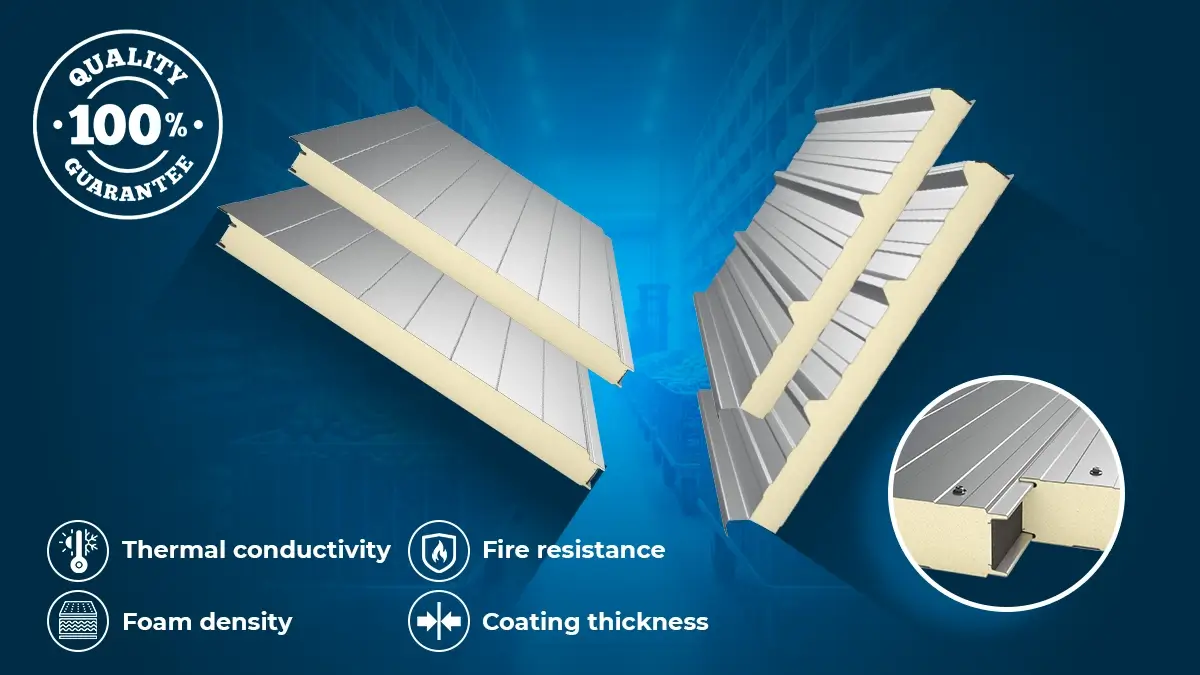

1. Check Quality of Raw Materials & Panel Profiles

High-quality PUF panels depend on:

✔ Strong metal skins

✔ High-density PUF core (40 ± 2 kg/m³)

✔ Continuous & uniform foam density

✔ Strong adhesion during production

Your supplier must offer a complete range of panel profiles based on your application.

EPACK Prefab manufactures:

✔ Cold Storage PUF Panels (Camlock System)

Designed specifically for cold rooms, deep freezers & ripening chambers.

✔ Roofing PUF Panels

Lightweight, highly insulated & ideal for industrial roofing.

✔ Wall PUF Panels

Used in prefab buildings, clean rooms & industrial partitions.

✔ Micro Rib & Plain Finish Panels

For clean aesthetics in commercial and industrial buildings.

EPACK ensures strict quality checks at every stage with in-house lab testing of:

- Thermal conductivity

- Fire resistance

- Foam density

- Coating thickness

2. Advanced Manufacturing Technology – Look for a CP Line

Most suppliers use basic or semi-automatic machines, which leads to:

✘ Density variation

✘ Weak bonding

✘ Uneven thickness

✘ Lower insulation performance

EPACK Prefab eliminates these issues with its NEW Advanced Continuous Panel (CP) Line, one of the most modern panel manufacturing lines in the country.

Highlights of EPACK’s Advanced CP Line

- Fully automated continuous production

- Uniform foam density across the entire panel

- Zero gap & zero thermal leakage

- Faster output, ensuring quicker delivery

- Consistent quality for every panel

- Ability to manufacture long, joint-free panels

This ensures world-class panels suitable for cold storage, pharma, logistics, industrial sheds, and food processing facilities.

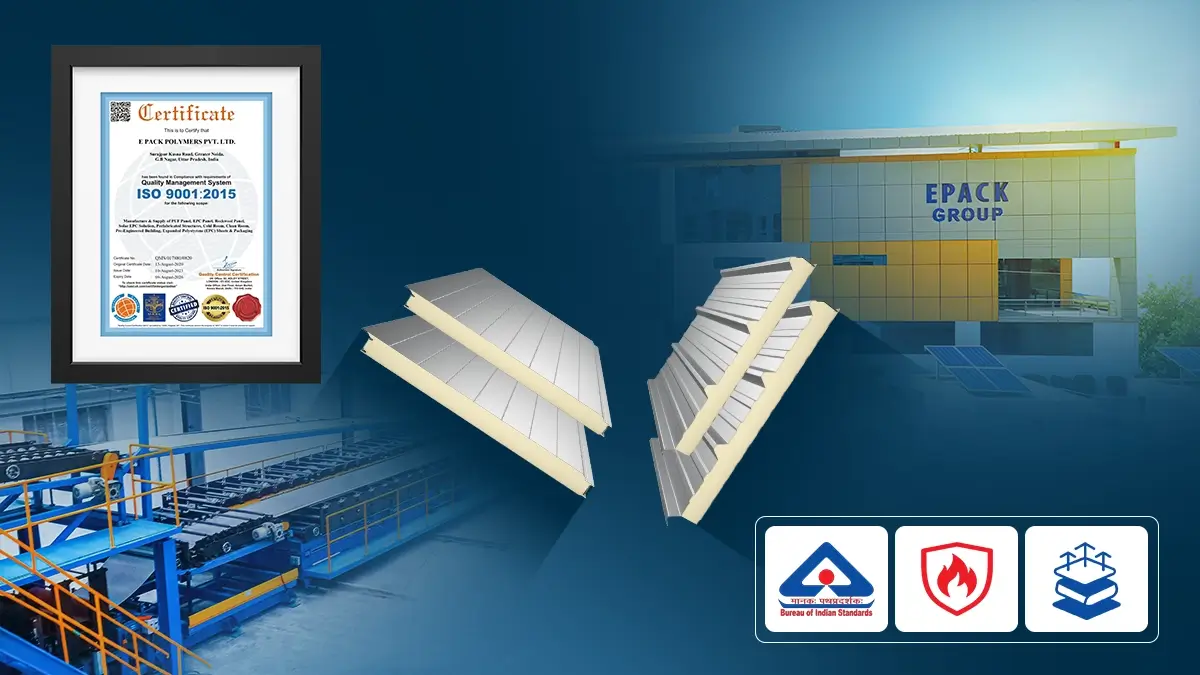

3. Certifications, Standards & Compliance

Before choosing any supplier, ensure they comply with leading standards:

✔ ISO 9001:2015

✔ BIS/IS Standards

✔ Fire compliance certifications

✔ Test reports on panel strength & insulation

EPACK Prefab checks all the boxes, offering PUF panels manufactured through stringent quality control with adherence to national and international guidelines.

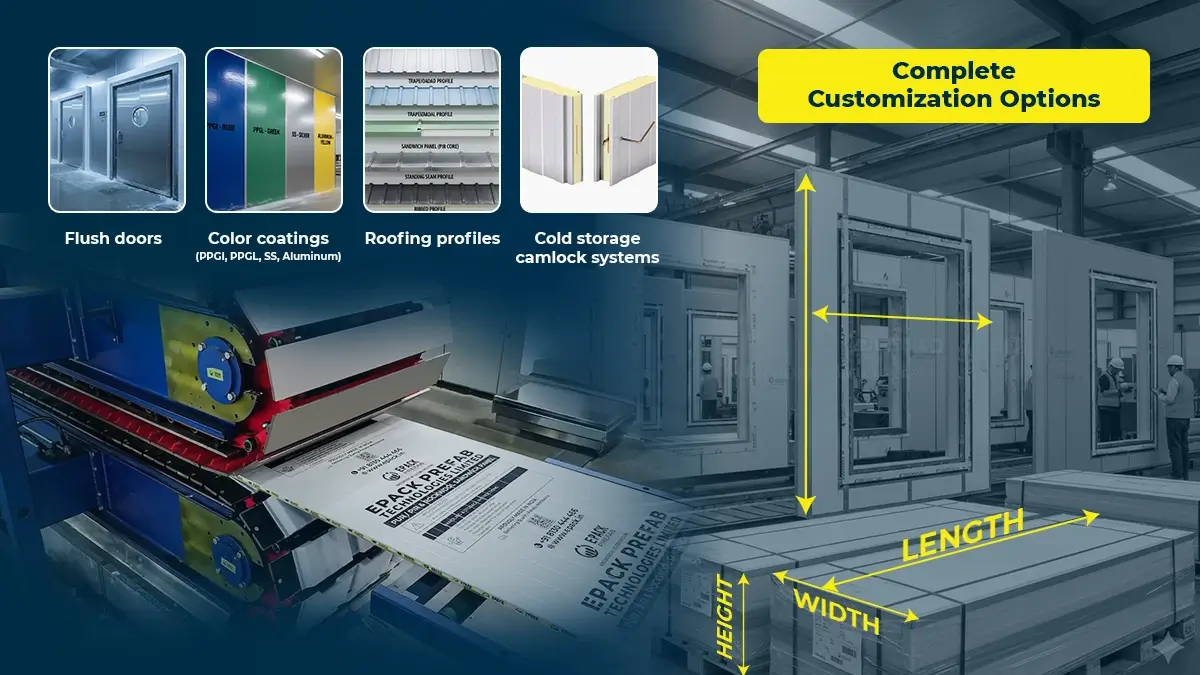

4. Customization Options & Application-Specific Solutions

Each project has different insulation and design needs. Your supplier must offer complete customization in:

- Thickness options (30 mm to 200 mm)

- Color coatings (PPGI, PPGL, SS, Aluminum)

- Panel lengths & widths

- Cold storage camlock systems

- Flush doors, cleanroom doors, view panels

- Roofing profiles

- Joint systems

EPACK Prefab specializes in customized solutions for:

✔ Cold Storage & Ripening Chambers

✔ Clean Rooms (Pharma, Electronics, Food)

✔ Prefab Buildings

✔ Defence & Government Projects

✔ Industrial Sheds & Enclosures

You’ll never have to compromise on performance or aesthetics.

5. PAN-India Presence, Faster Deliveries & After-Sales Support

Your supplier must provide:

- Quick delivery

- Hassle-free logistics

- PAN-India coverage

- Dedicated technical support

- Warranty & installation guidance

EPACK Prefab excels with:

✔ Multiple Manufacturing Plants

- Greater Noida (Head Plant) – Serving North, West & East India

- Mambattu, Andhra Pradesh (South India CP Line Plant) – Serving South & Central India

✔ Strong PAN-India Supply Network

EPACK delivers to:

- Metro cities

- Industrial zones

- Food processing hubs

- Cold chain clusters

- Remote locations and tier-2/3 cities

✔ On-Site Technical Support

Our engineering teams assist with:

- Panel selection

- Installation guidance

- Cold storage building layout

- Technical detailing

Why EPACK Prefab Is the Right PUF Panel Supplier for India

EPACK Prefab offers unmatched advantages:

✔ 25+ Years of Manufacturing Experience

✔ One of India’s Most Advanced Continuous Panel Lines

✔ Specialized Cold Storage & Cleanroom Panel Profiles

✔ Complete Prefab & PEB Solutions Under One Roof

✔ 7400+ Successful Industrial & Commercial Projects Completed

✔ PAN-India Reach with Fast Deliveries

From cold room panels to large industrial structures, EPACK is trusted across India for quality, innovation, and reliability.

Conclusion

Choosing the right PUF panel supplier is crucial for ensuring:

✔ Energy savings

✔ Long-term durability

✔ Perfect insulation

✔ Hassle-free installation

✔ Smooth project execution

Evaluate your supplier based on **quality, technology, certification, customization, logistics, and support—**and you’ll never go wrong.

If you’re looking for reliable, high-quality PUF insulated sandwich panels for your next project…

📞 +91-8130444466

📩 enquiry@epack.in

EPACK Prefab is ready to deliver India’s finest PUF panel solutions right to your project site.