India’s industrial construction landscape is undergoing a major transformation. In 2026 and beyond, industries are no longer focused only on building structures—they are focused on speed, scalability, energy efficiency, and long-term performance.

Traditional construction methods, dependent on heavy on-site work and longer timelines, are increasingly unable to meet these demands. This is where Pre-Engineered Buildings (PEB) and Prefabricated Structures are redefining the future of industrial construction in India.

This blog explains how PEB and prefab structures are shaping the next phase of India’s industrial growth and why they have become the preferred construction choice across sectors.

India’s Industrial Construction Needs Are Changing

Industrial growth today is driven by:

- Manufacturing expansion

- Logistics and warehousing growth

- Cold chain and food processing

- Renewable energy and power projects

- Data centres, automobile, cement, and heavy engineering sectors

These industries require infrastructure that can be built faster, expanded easily, and operate efficiently over decades. PEB and prefab construction meet these expectations better than any conventional approach.

What Are Pre-Engineered Buildings (PEB)?

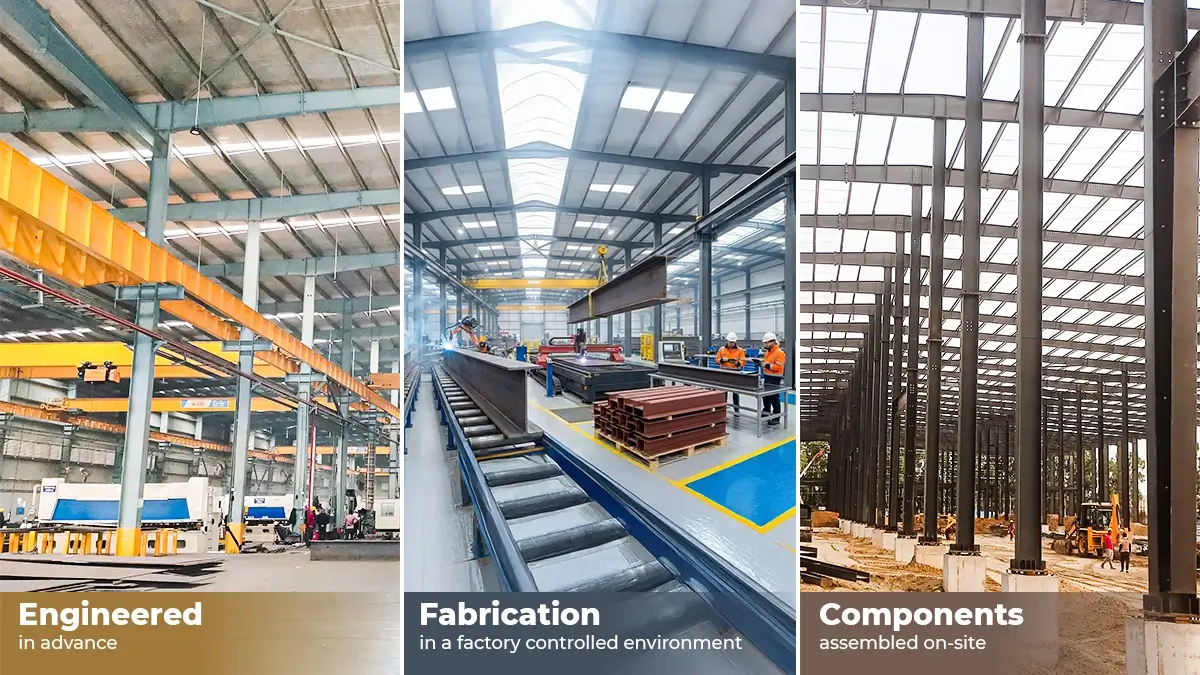

Pre-Engineered Buildings are steel-based structures where:

- Structural components are designed and engineered in advance

- Fabrication is done in a factory-controlled environment

- Components are assembled on-site using bolted connections

PEB systems are commonly used for:

- Industrial sheds

- Factories and manufacturing plants

- Warehouses and logistics hubs

- Aircraft hangars and large-span structures

The key advantage of PEB lies in engineering optimization, which reduces steel consumption while maintaining high structural strength.

What Are Prefabricated Structures?

Prefabricated structures go beyond steel frames. They include:

- Insulated sandwich panels (PUF, Rockwool, Glass Wool, EPS)

- Prefabricated walls and roofing systems

- Modular enclosures and site infrastructure

- Factory-finished building components

These elements are manufactured off-site and installed quickly at the project location, ensuring precision, speed, and quality consistency.

Why PEB & Prefab Structures Are the Future of Industrial Construction

1. Speed of Construction

Time-to-market is critical for industrial projects. PEB and prefab structures offer:

- Parallel execution of foundation work and fabrication

- Faster installation compared to conventional construction

- Reduced dependency on weather conditions

This enables industries to start operations sooner, improving return on investment.

2. Cost Efficiency Over the Project Lifecycle

While initial planning is more detailed, PEB and prefab structures:

- Reduce material wastage

- Lower labour dependency

- Minimise rework and maintenance costs

- Improve energy efficiency

Over the lifecycle of the building, these factors translate into significant cost savings.

3. Design Flexibility and Scalability

Industrial facilities often evolve over time. PEB and prefab buildings allow:

- Easy expansion without disrupting operations

- Modular additions

- Customised layouts based on process requirements

This flexibility makes them ideal for fast-growing industries.

4. Energy Efficiency and Sustainability

Modern industrial construction must meet energy and sustainability benchmarks.

Prefabricated structures support:

- High-performance insulation

- Reduced heating and cooling loads

- Lower carbon footprint

- Compliance with green building principles

Energy-efficient buildings are no longer optional—they are a necessity.

5. Quality, Safety, and Durability

Factory-controlled manufacturing ensures:

- Consistent quality

- Better safety standards

- Precision engineering

- Long service life

PEB and prefab structures are designed to withstand heavy loads, wind forces, and varying climatic conditions, making them suitable for long-term industrial use.

Key Industrial Applications of PEB & Prefab Structures

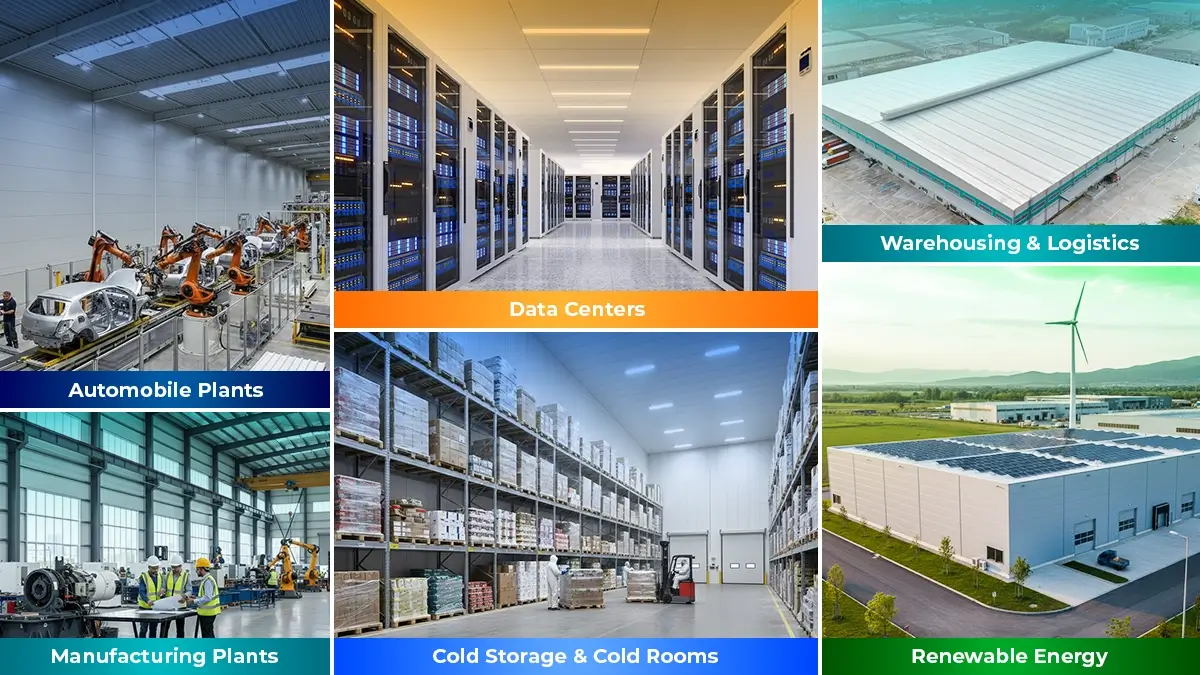

PEB and prefab systems are widely used across industries, including:

- Warehousing & Logistics: Large clear spans, fast delivery

- Manufacturing Plants: Optimised layouts for machinery and workflows

- Cold Storage & Cold Rooms: Energy-efficient insulated panels

- Renewable Energy Projects: Site infrastructure and utility buildings

- Data Centres: Controlled environments and fast deployment

- Cement & Automobile Plants: Durable, scalable industrial buildings

Their adaptability makes them a future-ready solution for diverse industrial needs.

How EPACK Prefab Is Shaping the Future of Industrial Construction

EPACK Prefab plays a key role in advancing industrial construction through:

- Pre-Engineered Building systems for large-scale industrial use

- Insulated sandwich panels manufactured using advanced Continuous Panel (CP) lines

- Multiple manufacturing plants with PAN India presence

- End-to-end solutions covering design, manufacturing, and supply

With 25+ years of experience and 7400+ projects delivered, EPACK Prefab supports industries with reliable, scalable, and energy-efficient construction solutions.

The Road Ahead for Industrial Construction in India

As India continues its push toward industrialisation and infrastructure development, PEB and prefab structures will become the standard, not the exception.

Their ability to deliver:

- Faster project completion

- Predictable costs

- Sustainable performance

- Future scalability

makes them the most practical construction solution for the coming decade.

Conclusion

The future of industrial construction in India is firmly rooted in PEB and prefabricated structures. These systems address the modern industry’s need for speed, efficiency, durability, and sustainability—without compromise.

For industries planning expansion or new facilities, adopting PEB and prefab construction is not just a smart choice—it is a strategic one.

To explore industrial construction solutions or discuss your project requirements, connect at enquiry@epack.in or call +918130444466