As energy costs rise and sustainability becomes a core business requirement, industries across India are rethinking how their buildings are designed and constructed. In 2026, one construction solution is clearly standing out—insulated sandwich panels.

From warehouses and factories to cold storage, data centers, and power sector buildings, insulated panels such as PUF, Rockwool, EPS, and Glass Wool panels are now a necessity rather than an option.

In this blog, we explore why insulated sandwich panels are critical for modern industrial infrastructure and how they help businesses reduce costs, improve efficiency, and meet sustainability goals.

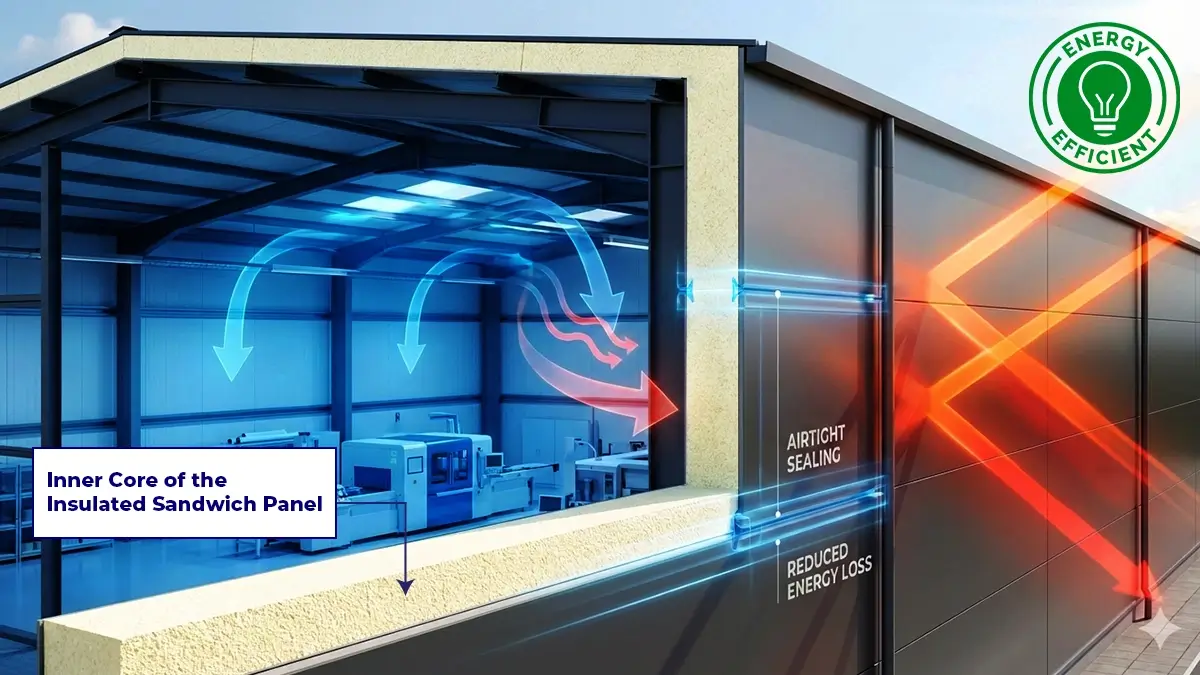

What Are Insulated Sandwich Panels?

Insulated sandwich panels are factory-made building components consisting of:

- Two outer metal sheets (GI / PPGI / Aluminium)

- An insulating core material such as PUF, Rockwool, EPS, or Glass Wool

These panels are used for:

- Walls

- Roofs

- Cold rooms

- Acoustic enclosures

- Fire-rated partitions

They are widely integrated with PEB and prefab structures for industrial and commercial projects.

Why Energy Efficiency Is a Priority for Industrial Buildings in 2026

India’s industrial sector consumes a significant share of electricity, especially for:

- Cooling

- Refrigeration

- Ventilation

- Climate-controlled processes

With rising power tariffs and stricter ESG requirements, businesses now demand buildings that:

- Reduce energy consumption

- Maintain internal temperature stability

- Lower carbon footprint

- Support green certifications

Insulated sandwich panels directly address these needs.

Key Benefits of Using Insulated Sandwich Panels

1. Significant Energy Savings

PUF and EPS panels provide excellent thermal insulation, reducing heat transfer and cutting HVAC energy consumption by up to 30–40%.

This makes them ideal for:

- Cold storage facilities

- Food processing units

- Pharmaceutical plants

- Data centers

2. Faster Construction Timelines

Sandwich panels are factory-manufactured and ready to install, which:

- Eliminates plastering and curing time

- Reduces on-site labor

- Accelerates project completion

This speed is crucial for industries aiming for faster operational readiness.

3. Fire Safety & Compliance

Rockwool and Glass Wool panels are:

- Non-combustible

- Fire-resistant

- Suitable for high-risk industrial environments

They are widely used in:

- Power plants

- Cement plants

- Automotive facilities

- Electrical substations

- Public infrastructure projects

4. Acoustic Performance

Glass Wool and Rockwool panels offer excellent sound absorption, making them ideal for:

- Acoustic enclosures

- DG rooms

- Compressor rooms

- Manufacturing floors

- Metro & airport buildings

They help industries comply with noise pollution regulations.

5. Long-Term Durability & Low Maintenance

Insulated panels are:

- Moisture-resistant

- Corrosion-protected (with proper coatings)

- Pest-resistant

- Easy to clean

This ensures a long service life with minimal maintenance costs.

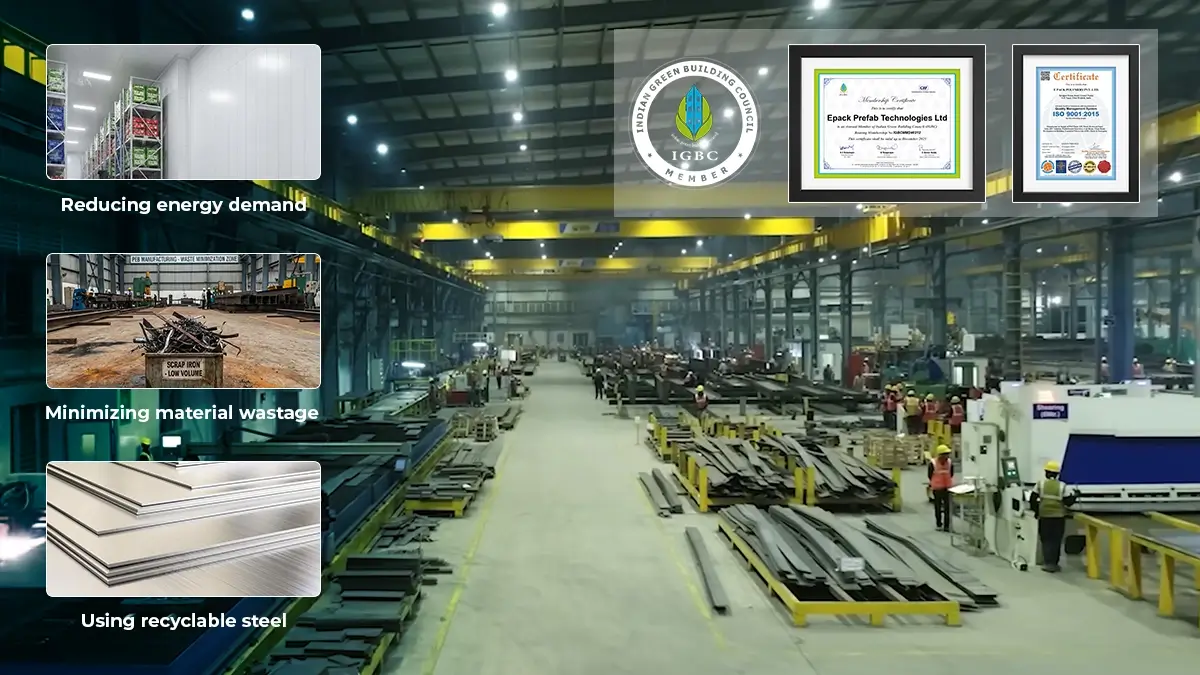

6. Sustainability & Green Building Alignment

Insulated panels support sustainable construction by:

- Reducing energy demand

- Minimizing material wastage

- Using recyclable steel

- Supporting green building certifications

They align with India’s long-term goals for energy efficiency and low-carbon infrastructure.

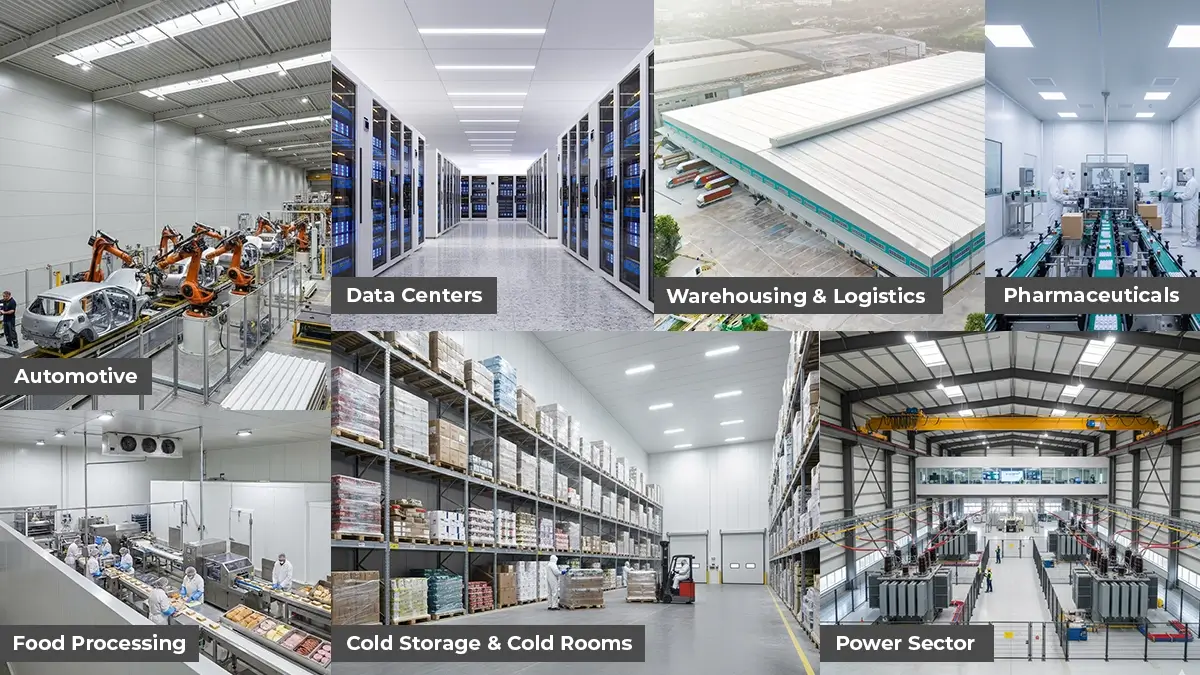

Applications of Insulated Sandwich Panels Across Industries

| Industry | Application |

| Cold Storage & Cold Rooms | Temperature control & energy savings |

| Warehouses & Logistics | Thermal comfort & faster construction |

| Pharmaceuticals | Hygienic, controlled environments |

| Food Processing | Compliance with safety standards |

| Data Centers | Thermal efficiency & noise control |

| Power Sector | Fire-rated & acoustic enclosures |

| Automotive & Manufacturing | Durable, scalable buildings |

Why EPACK Prefab Is a Trusted Insulated Panel Manufacturer

EPACK Prefab is one of India’s leading manufacturers of insulated sandwich panels and prefab structures, offering:

With:

- 25+ years of experience

- 7400+ projects delivered

- PAN India presence

- Advanced continuous panel (CP) production lines

- Multiple manufacturing plants

EPACK Prefab delivers high-quality panels and complete end-to-end infrastructure solutions for industrial and commercial projects.

Future Outlook: Insulated Panels Are No Longer Optional

As India moves toward:

- Higher industrial output

- Energy-efficient manufacturing

- Sustainable infrastructure

- Faster project execution

Insulated sandwich panels will continue to be a core building material across sectors.

Businesses that adopt this technology early gain:

- Lower operational costs

- Faster scalability

- Regulatory compliance

- Long-term asset value

Conclusion

Insulated sandwich panels are transforming how industrial buildings are constructed in India. Their ability to deliver energy efficiency, safety, speed, and durability makes them indispensable in 2025 and beyond.

If you are planning a new industrial project or upgrading an existing facility, choosing the right insulated panel solution can make a measurable difference to performance and cost.

📞 Build Smarter with EPACK Prefab

For insulated panels, cold storage solutions, or turnkey prefab buildings:

📧 enquiry@epack.in

📞 +91 8130444466

Let EPACK Prefab help you build efficient, future-ready infrastructure.