India’s manufacturing sector is expanding at an unprecedented pace. With the Government’s push through Make in India, rising global demand, and rapid industrialization across Tier-2 and Tier-3 cities, businesses today need infrastructure that is fast, scalable, and cost-effective.

This is exactly why prefabricated industrial sheds—built using modern PEB and prefab technologies—are becoming the preferred choice for industries ranging from automotive to logistics to FMCG.

In this blog, let’s explore why prefabricated industrial sheds are transforming India’s industrial landscape and how EPACK Prefab helps businesses build smarter.

What Are Prefabricated Industrial Sheds?

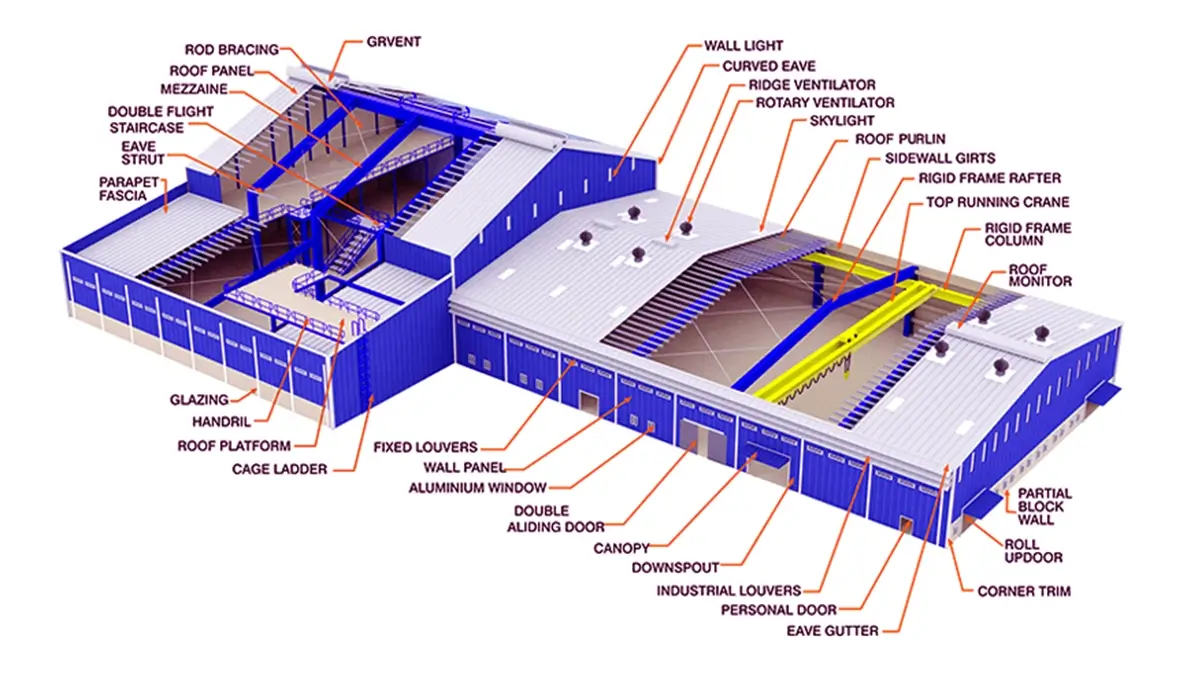

Prefabricated industrial sheds are modern steel structures made using Pre-Engineered Building (PEB) technology.

Instead of constructing everything on-site (which is slow and expensive), components like columns, rafters, purlins, and insulated panels are manufactured in a factory and assembled at the site.

These structures are widely used for:

- Manufacturing units

- Warehouses & storage godowns

- Automotive assembly sheds

- Cement & steel industry plants

- Logistics & distribution hubs

- Data-center enclosures

- Power sector utility buildings

Why Industrial Sheds Are Moving From RCC to Prefab Steel Structures

Traditional RCC structures cannot meet today’s speed, flexibility, and cost requirements. Prefab steel buildings solve all these challenges—here’s how:

1️⃣ Faster Construction for Rapid Expansion

Prefabricated industrial sheds cut construction time by 40–60%.

This speed helps industries start operations faster, reduce project delays, and improve ROI.

With EPACK Prefab’s automated PEB production lines, components are manufactured with precision, ensuring quick site installation.

2️⃣ Highly Durable and Weather-Resistant

Steel industrial sheds remain unaffected by:

- Heavy rainfall

- High temperatures

- Wind loads

- Seismic activity

They also resist pests, corrosion (with proper coating), and fire when combined with insulated sandwich panels like:

- PUF Panels for thermal insulation

- Rockwool Panels for fire resistance

- Glass Wool Panels for acoustic control

3️⃣ Energy Efficiency Through Insulated Panels

Modern industrial sheds must reduce energy usage, especially in climate-sensitive operations.

EPACK Prefab offers factory-made insulated panels:

- PUF Cold Room Panels

- PUF Roofing & Wall Panels

- Rockwool Panels for fire-safety

- Glass Wool Panels for sound insulation

These panels reduce heating & cooling loads by up to 40%, making operations more sustainable.

4️⃣ Easy Expansion & Modifications

As businesses grow, they often need to expand the structure.

Prefab sheds allow easy extension:

- Add new bays

- Increase height

- Add mezzanine floors

- Modify internal layouts

All without major downtime or demolition.

5️⃣ Cost-Effective for Long-Term Use

Prefab sheds reduce costs through:

- Faster construction

- Minimal material wastage

- Reduced labor requirements

- Lower maintenance

- Longer structural life

Businesses get higher value for every rupee invested.

6️⃣ Safer & Compliant With Industry Standards

Industrial sheds must follow strict safety norms—especially in:

- Power sector

- Cement manufacturing

- Chemical plants

- Automotive assembly lines

EPACK Prefab ensures compliance with:

- IS codes

- Fire safety norms

- Environmental & thermal standards

- Structural load requirements

7️⃣ Ideal for Renewable Energy & Green Buildings

Prefab steel sheds support India’s sustainability goals:

- Fully recyclable steel

- Reduced carbon footprint

- Compatibility with solar PV installations

- Support for green factory certifications

8️⃣ PAN-India Manufacturing & Delivery

EPACK Prefab operates multiple manufacturing plants, including the advanced Continuous Panel (CP) line at our South India facility—enabling fast delivery of:

- Cold storage panels

- Roofing & cladding panels

- Structural steel components

This makes us the preferred partner for large-scale industrial clients across India.

Top Industries That Prefer Prefabricated Industrial Sheds

| Industry | Why They Prefer Prefab Sheds |

| Automotive | Large clear spans, fast expansion |

| Renewable Energy (Solar/Wind) | Quick setup, durable enclosures |

| Warehousing & Logistics | Cost-efficient, tall structures |

| Cement & Steel | Heavy-duty structures, strong RCC alternatives |

| Food Processing | Hygienic PUF-panel interiors |

| Pharmaceuticals | Temperature-controlled insulated units |

| Power Sector | Substation buildings, acoustic enclosures |

Why Choose EPACK Prefab for Industrial Sheds?

✔ 25+ years of industry leadership

✔ 7,400+ projects delivered

✔ PAN-India presence & multiple factories

✔ Advanced CP line for high-quality panels

✔ Expert engineering & customized solutions

✔ Trusted by India’s leading manufacturing brands

From structural design to panel supply to full turnkey execution—EPACK Prefab delivers industrial sheds that are fast, durable, and future-ready.

Conclusion

Prefabricated industrial sheds aren’t just a trend—they are becoming the foundation of India’s industrial revolution. With faster construction, better energy efficiency, and superior durability, these structures help companies scale faster and operate more efficiently.

If your business is planning expansion or setting up a new facility, prefab steel structures are the smartest choice.

📞 Plan Your Industrial Shed With EPACK Prefab

For enquiries or project discussions:

📧 enquiry@epack.in

📞 +918130444466

Let EPACK Prefab build a structure that drives your business forward.