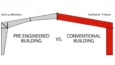

One of the goods within the modular building market that is experiencing the greatest level of demand right now is prefabricated industrial sheds. These storage spaces are also known as pre-engineered steel sheds, and they provide a high degree of adaptability. They are used for a variety of purposes, including as factory sheds, warehouses, agricultural buildings, chicken sheds, and many other types of structures. In what ways, then, are these structures distinct from conventional manufacturing buildings? However, there are many distinct variances. PEB industrial sheds are buildings that require little to no maintenance and may be delivered more quickly. They enable for easy extension and are able to withstand adverse environmental conditions.

Because of its flexibility, durability, and adaptability, pre-engineered steel sheds have grown extremely popular in the building sector over the past few years. This popularity may be attributed to the benefits that this material has to offer. In this article, we will investigate some of the most significant advantages that have contributed to the rising demand for these shelters.

PEB industrial sheds are structures that require little to no upkeep

The outside of an off-site prefabricated building requires relatively minimal upkeep and care, and this is true regardless of the material that is used in its construction. In contrast to traditional buildings, which need to have their exteriors painted every few years, PEB shelters are constructed with pre-painted galvanised sheets. These sheets have a lifespan of many years.

There is no reason to be concerned about any damage that may have been caused by termite infestation or the growth of mould or mildew if your prefab industrial shed was constructed out of steel. As a result, your PEB steel shed is a building that requires very little care from every vantage point. It is extremely unlikely that damage will develop as a result of environmental causes, which is something that occurs frequently in conventional buildings.

PEB steel shelters are known for their durability

Because of its long lifespan, prefabricated industrial sheds are an attractive investment opportunity for business owners. Steel has a natural tendency to survive for a long time and is therefore capable of withstanding adverse climatic conditions. Prefabricated industrial shelters are built to last for many years without requiring any significant repairs or upkeep of any kind. Because pre-engineered steel buildings are not flammable, there is no need for concern over the possibility of any harm being caused by fire.

They are sustainable in addition to being environment friendly

The fact that PEB industrial sheds aren’t harmful to the surrounding ecosystem is the third major advantage they offer. Traditional structures generate significantly more trash than their metal counterparts, which are manufactured from steel. A significant portion of the steel that is utilised in the building industry today is recyclable for use in other industries. This ensures that the environment will not be harmed in the event that your prefabricated industrial shed is destroyed at some point in the future. Instead of being thrown away at a landfill, the steel structures could be put to use in another setting.

There is a sufficient amount of attention placed on the preservation of the environment due to the growing population everywhere. The building industry has also turned to innovative techniques and cutting-edge technology in order to produce environmentally friendly structures. In addition to being a component of the green building solutions, PEB industrial shelters are also available.

EPACK Prefab is one of the premium industrial shed manufacturers in India that has experienced the most rapid growth. We are the leading manufacturer of pre-designed factory buildings, warehouses, and a wide variety of other building types that have various applications for steel sheds. The criteria for the product’s size, paint, finish, and wall and roof claddings are followed carefully during production. With over 24 years of expertise, we are fully engaged in the manufacturing of PEB systems, and we serve clients from the industrial, commercial, and institutional sectors equally.